Discover Freudenberg S.A.F.E.air

Cabinet Filtration Systems

Benefit from Freudenberg expertise now

Greater return on investment

S.A.F.E.air Pressurisation & Filtration solutions protects equipment and workers while maximising production.

- Extended maintenance cycles

- Reduced maintenance downtime

- Improved equipment reliability

- Cabinet dust protection and extraction

- Electrical cabinet filters

- Plant room filtering and dust control

Future-proofing your mine site

S.A.F.E.air has been developed to meet the current and future needs of the mining industry.

- Freudenberg's high efficiency particulate air (HEPA) filters extract particulate matter as small as 0.1μm

- S.A.F.E.air cabinet filtration protect electronics and equipment from dust

- S.A.F.E.air room filtration protect plant rooms from particulate matter that could damage mining plant.

In addition to cabinet protection, S.A.F.E.air cabin pressurisation and filtering units provide protection for drivers. S.A.F.E.air Cabin units are designed to exceeds the requirements for the ISO 23875 Standard.

S.A.F.E.air Cabinet Protection

The Problem

The factory system pulls air through the cabinet, it is drawn down into a negative pressure causing dust and contaminants to enter through the low efficiency filter and any cabinet opening. This creates dust ingress into the electrical cabinet which controls the autonomous vehicle.

Over time, dust and particulate matter accumulates and can cause damage to wiring and equipment, leading to:

- increased frequency of maintenance

- higher maintenance costs

- a decrease in production productivity due to the vehicle being unavailable while repairs are undertaken.

WorkAirTech Case Study

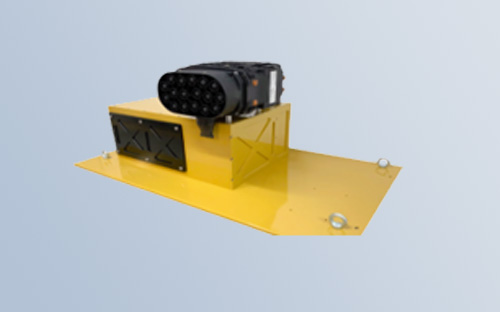

Terex MT4400AC Haul Truck S.A.F.E.air Cabinet Pressurisation Unit Trial

Before installing S.A.F.E.air to protect the control equipment cabinet on a Terex MT4400AC haul truck:

- The truck had a break-down every 3 days with an average down time of 44 minutes

- Maintenance electricians and operators raised health concerns due to having to blow out dust from components with compressed air, creating a risk of inhaling airborne particulate matter.

- Cleaning was expensive as skilled qualified electricians were required to facilitate the clean out.

Terex MT4400AC Haul Truck Trial Objectives

The objectives of the trial of the S.A.F.E.air Cabinet Protection System were to:

- Minimise truck down-time, specifically eliminate the frequent cause of contaminated propulsion cards leading to break-downs

- Increase cabinet cleaning intervals from 500hrs to 1000hrs+

- Mitigate personnel safety risk by minimising possibility of accumulate dust in the cabinet becoming airborne, and therefore potentially respirable, through maintenance/cleaning activities in the cabinet.

- Extend Operational Life of electronic components

- Reduce machine TCO through increased machine up-time & cost savings realised through extending service life of electrical componentry the control cabinet.

- Continuity & uniformity with supply of further kits and spares

Trial Testing Parameters

Two trucks were compared during the trial:

- Truck 1 had a S.A.F.E.air Cabinet Protection Unit installed.

- Truck 2 remained unmodified to use as the performance baseline.

Both trucks had their Planned Component Replacement (PCR) schedules set to coincide with each other with identical works undertaken. Both trucks received a High Voltage Cabinet reseal plus new IGBT seals were fitted in the PCR. WorkAirTech’s filtered pressuriser was installed on Truck 1 concurrent to these works.

Planned weekly monitoring of the High Voltage Cabinets on both trucks was conducted for the 8 weeks following trial commencement, but was cut short due to Truck 2 (no pressuriser) having requirement for a premature PCR, as dust accumulation in the HV Cabinet was resulting in electrical faults and in turn, break downs. Photos were taken of Truck 2’s HV Cabinet at 8 weeks and Truck 1 continued to operate seamlessly. Photos of Truck 1’s HV Cabinet for comparison were taken at trial conclusion, or at 20 weeks.

The Solution

The S.A.F.E.air cabinet pressurisation plug and play filtration system, pushes pressurised clean HEPA filtered air at a high flow through the cabinet and out the original filter opening, maintaining a constant cooling airflow through the cabinet.

The S.A.F.E.air system then uses a proven high efficient particle separation filter before passing through a second stage precleaning filter and finally through the high flow HEPA filters. The two precleaning elements protect the HEPA filters from heavy dust exposure and ensures longer HEPA filter life.

The electrical cabinet is kept dust and contaminate free, reducing heat build up of the modules, ensuring components have longer life, maintaining vehicle availability and reducing maintenance costs.

Trial Outcomes

At the conclusion of the trial, the client was extremely satisfied with the efficiency of the S.A.F.E.air filtered pressuriser. They placed an order to retrofit to the balance of their fleet of 22 haul trucks. 22 S.A.F.E.air Cabinet Pressurisation kits were manufactured at WorkaAirTech HQ in Perth and dispatched within 2 x weeks. The client was able to easily retrofit S.A.F.E.air units to their fleet and easily achieved their ROI within the first 2 months with HEPA elements easily operating for over 3000 Hrs due to the effectiveness of WorkAirTech’s market unique Pre-Filter/Pre-Separator.

The trial clearly achieved it's objectives:

- Minimised truck down-time

- Increased cleaning intervals to 1000hrs+

- Mitigated personnel safety health risks

- Extended operation life of components

- Reduced total cost of maintenance

- Provides continuity and uniformity across the fleet following implementation of S.A.F.E.air Cabinet Pressuration Units on all vehicles.

Freudenberg S.A.F.E.air cabin protection systems offer an alternative to other cabin pressurizer units for sale and technologies in the marketplace like Sy-Klone RESPA powered dust prevention systems.

S.A.F.E.air Cabinet Air Filtration and pressurisation systems for staff driving heavy machinery in potentially harmful environments.

Download brochure outlining how S.A.F.E.air elect

Want to know more about S.A.F.E.air or have a question?

Contact us for an obligation free site/fleet review on how

S.A.F.E.air Air Filtration and Pressurisation systems

can improve your operations

Freudenberg Filtration Technologies

S.A.F.E.air Electronics Cabinet Filter | S.A.F.E.air Cabin Pressurizer Units | S.A.F.E.air Pressurisation Filtration | Cabin Pressurizer units for sale

Language / Country

Language / Country