Freudenberg S.A.F.E.air:

Mining Industry Dust Protection

Discover Freudenberg solutions for ISO 23875 Compliant Mining Industry Cabin Pressurisation & Filtration Systems

Small particles – big impact

Why filtration

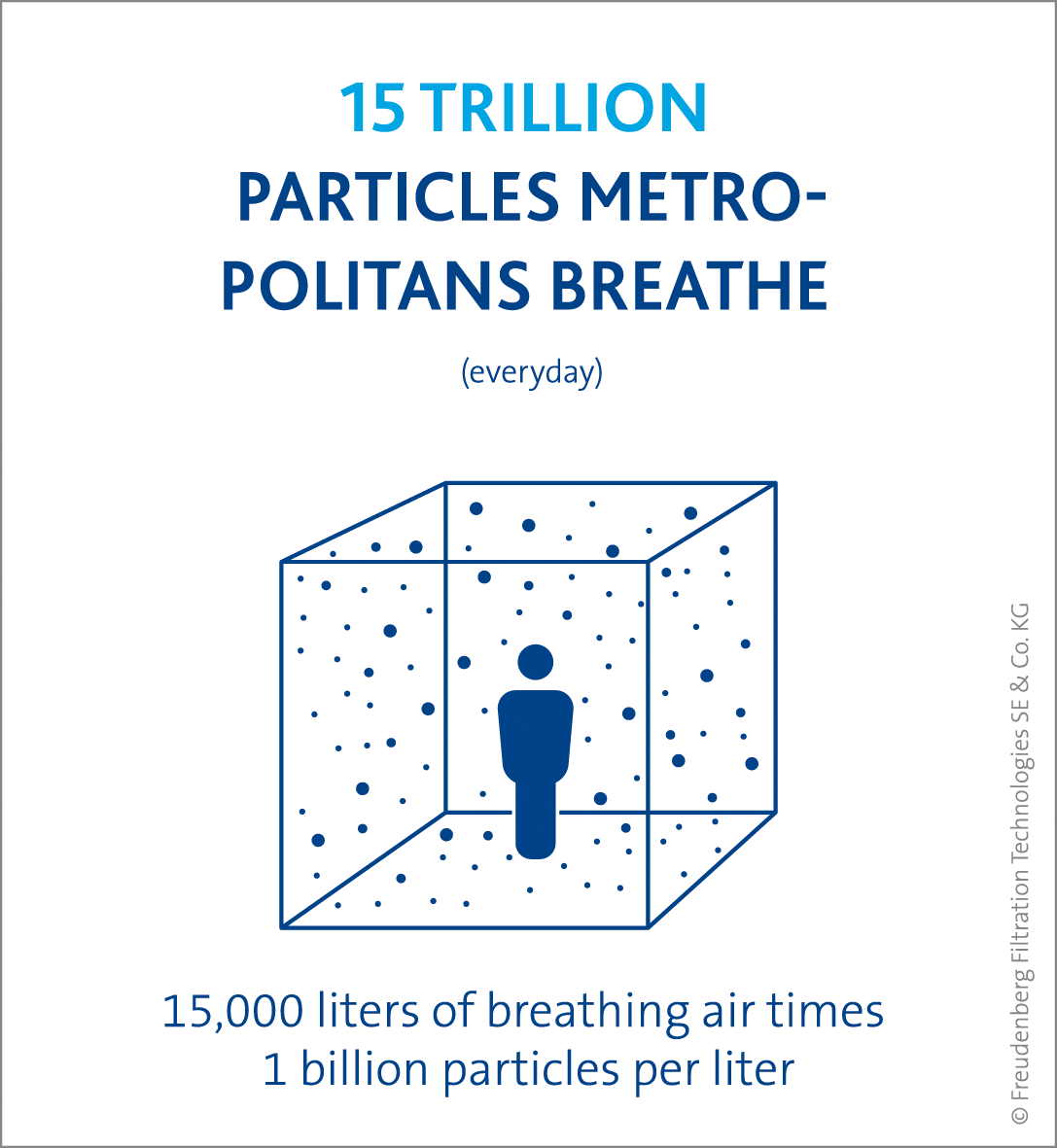

Like clean water, clean air is also an elixir of life: invisible but indispensable. People breathe every four seconds, that is roughly 22,000 breaths every day. In 24 hours, each of us breaths in about 15,000 liters of air.

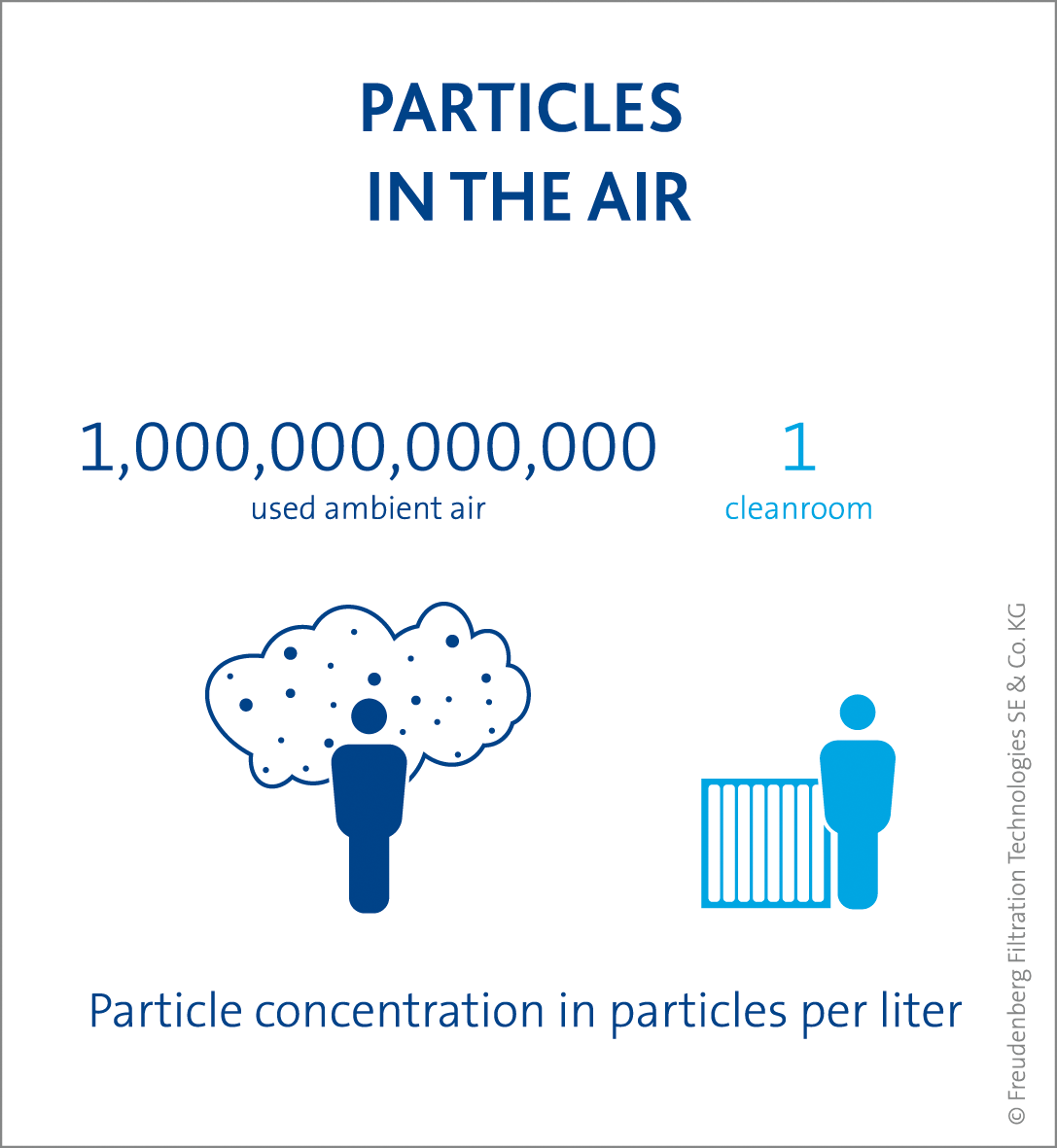

With every breath, large quantities of tiny particles enter our body. Even in presumably healthy rural air, there are millions of particles such as pollen, fungal spores, mold, soot, bacteria and viruses. In a large city, there are thousands of times as many particles, in the billions.

3 million!

Fine dust is particularly insidious.

The smaller the particle the more dangerous the dust is.

Over three million people die every year from the consequences of heavy air pollution with fine dust. In comparison with fine dust, small grains of sand are gigantic boulders. When inhaled, fine dust enters into the deeper respiratory tract and sometimes even moves directly into the blood.

Health alert! In vehicles and buildings, where we spend the majority of our time, the air is often much more contaminated than outdoors. Not to mention smoky indoor air with 100 billion particles per liter.

This is why it is so reassuring that Freudenberg Filter Technologies filters and filter systems reliably separate the essential elements of life from the harmful pollutants. So that everyone can breath in deeply. With pure pleasure and a high quality of life! While out for a drive, at the theater, on a cruise ship or just passing the time in the office break room.

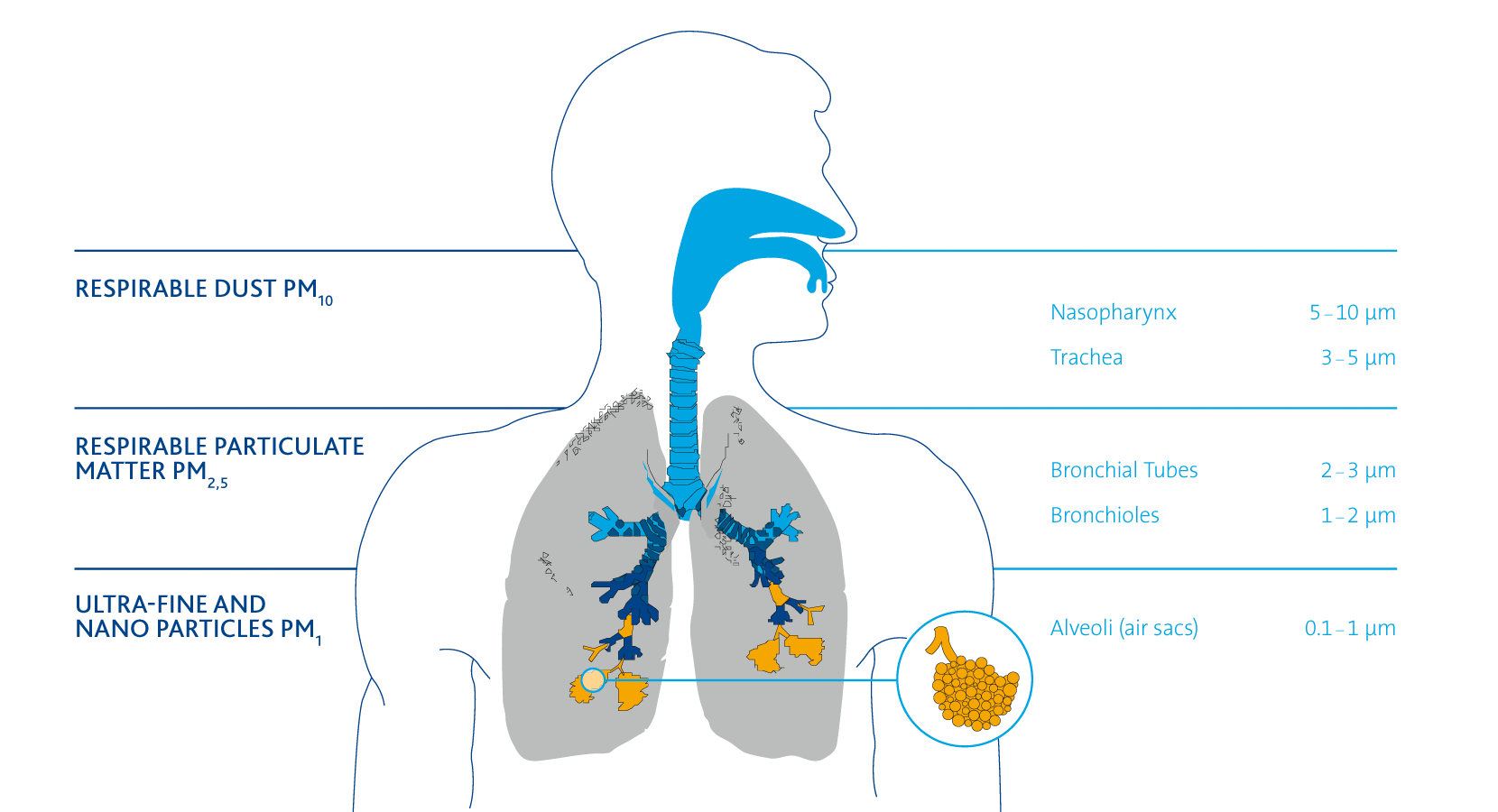

In the mining industry, the types of dust and particles that employees and equipment are presented with include

- respirable dust at around PM10 - which are about 5μm - 10μm in size that can reach the nasopharynx and trachea. Airborne dust clouds from vehicles driving and equipment excavating products is around this size of particulate matter.

- respirable particulate matter around PM2.5 - 2μm - 3μm that can be inhaled deeper and affect bronchial tubes and bronchioles. Finer dust from mining activities, as well as larger particulates in diesel exhaust are around PM2.5.

- ultra-fine and nano particles at PM1 - These are particles between 0.1μm and 1μm that can reach all the way into alveoli in the lungs - the air sacs inside your lungs. Micro particles like soot particulates in diesel exhaust, and fine dust from excavations are PM1. Even when trying to keep particulate matter outside the cabin, used exhaled air from the operator can be problematic causing driver fatigue through a lack of fresh air.

Particulate matter can be either natural or man-made.

Man-made sources of particulate matter include:

Cars and trucks, incinerators, power and heating plants, stoves and heaters in the home or within agricultural and industrial processes. In mining, vehicle activities also plays a significant role. Diesel nanoparticles are s created from diesel exhaust, diesel soot, fine brake and tire wear and road dust.

Natural sources of particulate matter include:

Emissions from volcanoes and seas, soil erosion, forest and brush fires, viruses, bacterial and fungal spores, and algae or cell particles. Mining raw materials create particulate matter as well such as iron ore dust and silica dust. Silica protection is of critical importance for employee health as it is a primary cause of mine dust lung disease.

ISO 23875 compliant S.A.F.E.air mining filtration products are designed to minimise the risk from all of these types of particulate matter.

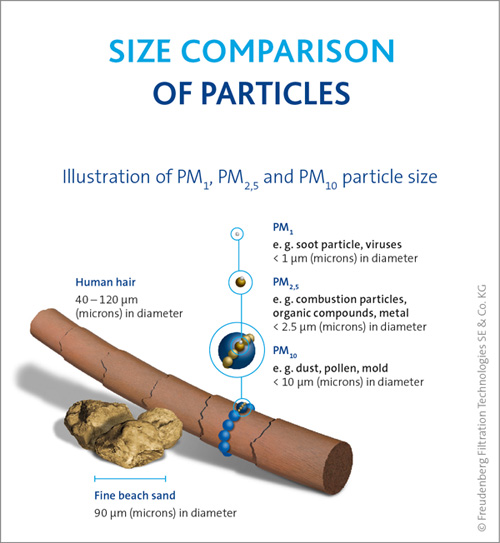

The terms “particulate matter” (PM) or “suspended particulate matter” refer to small to tiny particles

These tiny particles, which float for a while in the atmosphere and do not immediately fall.

Particles are divided into groups according to size.

Dust particles with an aerodynamic diameter smaller than 10 microns (1 micron = 1 thousandth of 1 mm) belong in the PM10 class. Just image: an average human hair has diamter of 60-80 microns.

PM10 in turn consists of three subsets:

- Coarse

Particles in the size range from 2.5 to 10 microns - Fine (also PM2.5)

Finer particles in the size range of less than 2.5 microns - Ultra-fine

Tiny particles in the size range of less than 0.1 microns

Discover the Freudenberg S.A.F.E.air pressurisation and filtration solutions

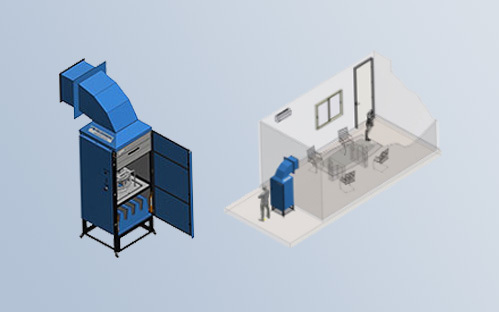

Innovative ISO 23875 Compliant Solution providing medical grade filtration

Failure to address the impact of dust in the mining industry can lead to employees suffering lung diseases or other health problems from fumes and diesel nanoparticles. S.A.F.E.air pressurisation and filtration solutions provide protection in mining and material processing environments, extracting particulate matter such as respirable crystalline silica, iron ore dust, and other nanoparticles that come from processing materials. Vehicle cabins are able to be protected from diesel nanoparticules, contaminent gases and provide silica protection, protecting operators from health hazards and preventing mine dust lung disease.

S.A.F.E.air solutions also provide improvements for operational considerations. Equipment cabinets, environmental enclosures and processing plant rooms can be filtered to prolong equipment life and extend the maintenance cycle by extracting dust and particulates during the operating cycle. Implementing ISO 23875 across your mining operation can reduce equipment downtime and maximise productivity through reduced maintenance outages and costs.

Freudenberg Filter Technologies Mining Products

Browse for more information on our S.A.F.E.air range and general mining filtration products.

ISO 23875 compliant S.A.F.E.air Filtration Solutions

Cabin, Room and Cabinet Pressurisation Solutions

Find out more about some of the ways S.A.F.E.air products can be implemented to improve air quality for employees and equipment, improve workforce health and safety, and reduce maintenance costs for plant and machinery while improving equipment reliability and minimising downtime.

Want to know more about S.A.F.E.air or have a question?

Language / Country

Language / Country