Diesel Oxidation Catalysts

FFT microfresh® catalytic converters are specifically designed for diesel, petrol, and LPG mining and related industry applications.

FFT microfresh® high temperature (catalytic) exhaust filtration technology includes Diesel Oxidation Catalysts, Continuous Regeneration Technology (CRT) ceramic filters and Partial Flow Filter (PFF) for Industrial and Mining Diesel Exhaust Filtration Applications.

FFT (Freudenberg Filtration Technologies) Diesel Exhaust filters:

FFT microfresh® high temperature (catalytic) exhaust filtration technology includes Diesel Oxidation Catalysts, Continuous Regeneration Technology (CRT) ceramic filters and Partial Flow Filter (PFF) for Industrial and Mining Diesel Exhaust Filtration Applications.

Microfresh® Particulate Catalysts can be fitted to any minesite equipment, even Open Cut operations can find their use beneficial on Haul Trucks where emissions can be problematic at pit bottom.

FFT has now developed high temperature Partial Flow Filter (PFF) technology for hardrock mines. The 100% stainless steel filters will reduce CO by up to 99%, hydrocarbons by 90%, NOx by 30% and most importantly carcinogenic Diesel Particulate by 85%. These filters have much lower maintenance requirements than traditional ceramic filters.

Even if mine sites are within emission level guidelines, the improvement in working conditions and associated productivity improvements would far outweigh any cost when installing Micro Fresh Catalysts.

PFF Filters - 4WD & Light Commercial

PFF Filters - Mining Fleet Vehicles

CRT Filters - Mining Fleet Vehicles

PFF Filter Efficiency

Murray Engineering offer a full service exchange / cleaning service for these PFF Catalytic Diesel Exhaust Filters and CRT Filters. Murray Engineering are a mining services company who understand underground machines, mining operations and the importance of reducing onsite maintenance concerns.

- Stainless Steel Foil (Substrate Core)

- Stainless Steel Grade 304 (Housing)

- Catalyst CPSI = 140

- Minimal Backpressure ( < 3.9" H20)

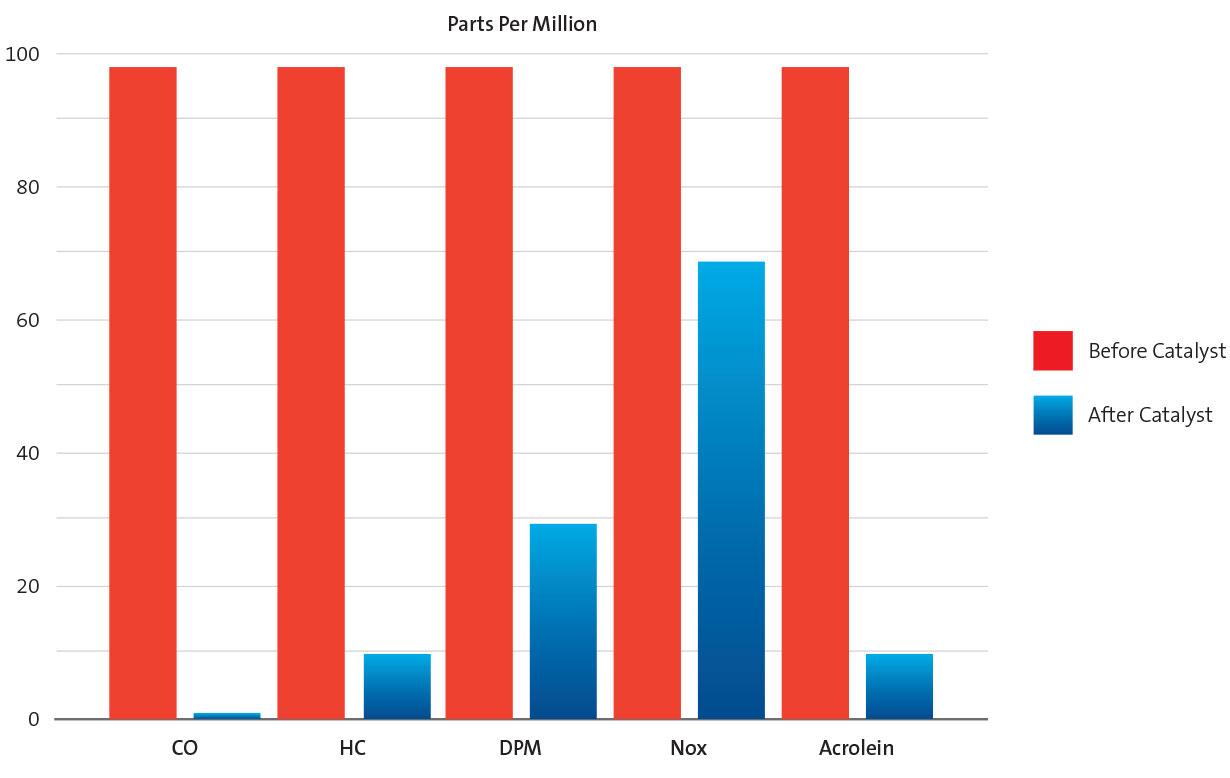

Catalyst Effectiveness

- CO (Carbon Monoxide) up to 99%

- HC (Hydrocarbons) up to 90%

- Acrolein up to 90%

- NOx (Nitrogen Oxide) up to 30%

- DPM (Diesel Particulate Matter) up to 60%-82%

Lifespan of Catalyst

- 3 to 5 years (8,000 to 10,000 hours)

Maintenance

- Designed to be maintenance free when installed on a regularly maintained engine.

- If maintenance is required simply unbolt catalyst and blow out in opposite direction of exhaust flow with high

- Pressure air or water (maximum 1600 psi recommended).

All catalysts are manufactured from premium grade stainless steel to prevent corrosion & promote durability. Most sizes can be shipped the same day order is placed and every catalyst is shipped with its own performance certificate.

Better still, microfresh® diesel oxidation catalyst installation is quick and easy and our catalysts are virtually maintenance free.

Freudenberg Filtration Technologies | Microfresh® Diesel Particulate Filter Catalysts Australia.

Language / Country

Language / Country