Forklift Diesel Particulate Filters and Catalyzed Mufflers

FFT Catalytic Diesel Exhaust Filters

PROTECT YOUR WORKFORCE FFT (Freudenberg Filtration Technologies) Catalytic Diesel Exhaust Filters are built for Forklifts to help improve air quality and protect the short and long term health of workers.

Freudenberg manufacture and supply diesel particulate filters and catalyzed mufflers for forklifts and other applications.

The Freudenberg Filtration Technologies range of diesel exhaust catalysts for forklifts are manufactured for varying diesel engine size and power.

We are renowned Diesel Particulate Filtration manufacturers, approved and preferred suppliers to the Australian Mining Industry.

FFT Forklift Diesel Particulate Filters and Catalyzed Mufflers

- Reduce Diesel Particulate Matter DPM output to help meet Euro 4/5 emission limits and the World Health Organisation IARC diesel exhaust classification as a Group 1 carcinogen

- Compact and lightweight compared to ceramic variants requiring no onboard electric management system

- Prevent DPM (Soot) & Carbon Monoxide build up in workshops, delivery bays or enclosed areas

- Significantly reduces DPM, CO and HC build up in enclosed spaces.

- Limit operator and employee exposure to harmful particulate matter, improving workforce health and morale

- Catalytic regeneration is not required; units are essentially maintenance free and have negligible back pressure signature

- Prevent EPA compliance fines or complaints, minimise down time with your fleet and improve productivity.

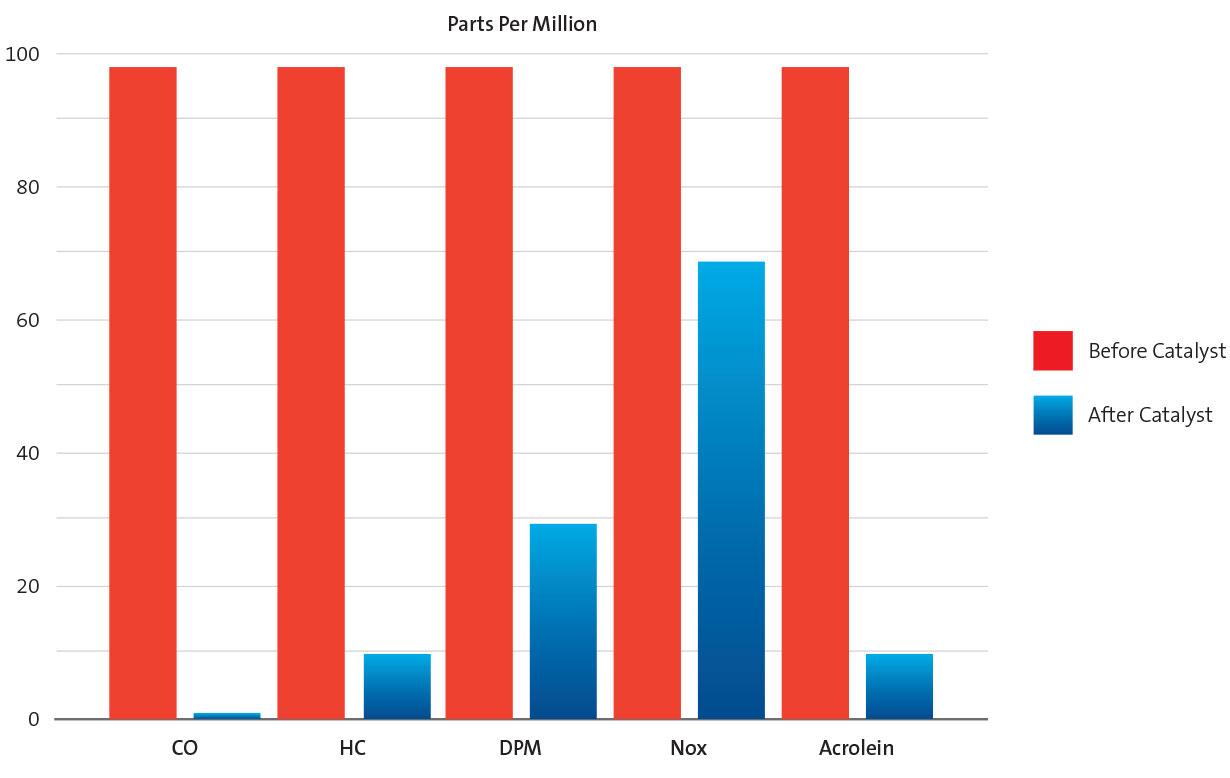

FFT Catalyst Effectiveness

- DPM (Diesel Particulate Matter) up to 70%

- CO (Carbon Monoxide) up to 99%

- HC (Hydrocarbons) up to 90%

- Acrolein up to 90%

- NOx (Nitrogen Oxide) up to 30%

Technical Specifications

| Engine Displacement (L) | Part Number | Length | Diameter | Weight |

|---|---|---|---|---|

| 0-1.9 | IC-3; IC-4 | 7.75” | 3-4” | 1.2-2.0 lb |

| 2.0-4.0 | IC-5 | 7.75” | 5” | 2.4 lb |

| 4.1-6.5 | IC-6 | 8-9” | 6” | 3.8 lb |

| 6.6-9.8 | IC-7 | 9-10” | 7” | 5 lb |

| 9.9-13.1 | IC-8 | 8.5-11” | 8” | 6 lb |

| 13.2-19.0 | IC-10 | 11” | 10” | 12 lb |

| 19.1 + | Contact Freudenberg Filtration Technologies Australia | |||

Catalyst & Housing Composition

- Stainless Steel Foil (Substrate Core)

- Stainless Steel Grade 304 (Housing)

- Catalyst CPSI = 140

- Minimal Backpressure (< 3.9” H20). Most engine manufacturers allow Up to 40” H20 (10 kPa). Other Diesel Particulate Filters run at 20”- 40” kPa.

Maintenance

- Designed to be maintenance free when installed on a regularly maintained engine.

- If maintenance is required simply unbolt catalyst and blow out in opposite direction of exhaust flow with high pressure air or water (maximum 1600 psi recommended). Appropriate PPE must be used. Please consult our company for details.

- Note that many other types of Diesel Particulate Filter require constant monitoring due to high back pressure and must be removed and baked in ovens regularly.

Operating Conditions for Successful Catalyst Use

- Exhaust Temperature must be at least 250° C (482° F) and not exceed 750° C (1382° F). Best reduction results are experienced when exhaust temperatures are between 350° C (662° F) and 600° C (1112° F).

- All catalysts are manufactured from premium grade stainless steel to prevent corrosion & promote durability

- Most sizes can be shipped the same day order is placed

- Installation is quick and easy.

Lifespan of Catalyst

- 3 to 5 years (8,000 to 10,000 hours).

Exhaust Pollutant Components & Their Effects

CO (Carbon Monoxide) = The deadliest and most watched of pollutants, CO if not removed from exhaust can upon exposure be very toxic and lethal. CO restricts the red blood cells ability to absorb oxygen molecules thereby suffocating the body. CO can be cancer causing.

Freudenberg Filtration Technologies - CO Reduction Rate: Up to 99%

HC (Hydrocarbons) = A very deadly and toxic pollutant, hydrocarbons are responsible for creating small irritants that can be easily absorbed into the lungs if not removed from the exhaust stream. Once in the lungs it can cause respiratory infections and shortness of breath. The harsh smell associated with all diesel engines is a byproduct of HC.

Freudenberg Filtration Technologies - HC Reduction Rate: Up to 99%

DPM (Diesel Particulate Matter) = Although not immediately lethal, prolonged exposure to these groups of pollutants can cause serious illness including cancer and respiratory problems. DPM is made up of dry carbon (soot), inorganic oxides (primarily as sulfates), and liquids. Liquids are a combination of unburned diesel fuel and lubricating oils which as a group are referred to as soluble organic fractions (SOF) or volatile organic fractions (VOF).

Freudenberg Filtration Technologies - DPM Reduction Rate: Up to 85%

Acrolein - Clear, colorless or yellowish liquid with a piercing, disagreeable odor.

Extremely flammable and toxic by inhalation or ingestion. Can cause tearing of the lung (Lachrymator). Will also cause irritation to skin and eyes.

Freudenberg Filtration Technologies - Acrolein Reduction Rate: Up to 90%

Freudenberg Filtration Technologies | Forklift Diesel Particulate Filters and Forklift Catalyzed Mufflers.

Language / Country

Language / Country