The effect of air filtration on gas turbine performance degradation

Test standard ISO 16890 and its application to real engine data

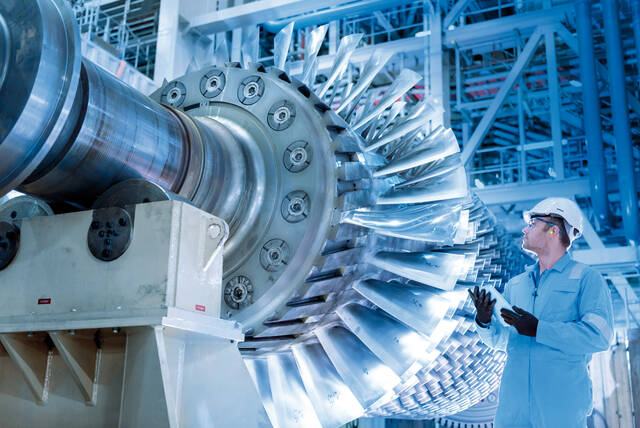

The degradation of gas turbine power output and compressor efficiency over time is strongly influenced by the amount and composition of particles entering the compressor. This amount is on one side affected by the chosen air filtration layout, and on the other side by the size distribution, mass and chemical composition of particles in the ambient air.

The introduction of the new global standard ISO 16890 brought a different approach to evaluate the filtration efficiency as a basis for filter classification: filter efficiencies will be determined with regard to separation efficiencies for particulate fractions PM1, PM2.5 and PM10.

In our White Paper you will learn more about the correlation between power output, respectively compressor efficiency degradation, the performance of installed air filters and the concentration and mass distribution of dust particles at the gas turbine’s location. Real world engine data from F-class gas turbines were recorded over several years, taken at different gas turbines around the world with 50 filter cycles summarized in 20 filter configurations.

Benefit from our specialized expertise in gas turbines and compressors.

Request detailed information

Filter efficiency calculation with e.FFECT

Find your optimum filtration solution

Ask our filter experts for a calculation with Freudenberg’s e.FFECT software (electronic Freudenberg Filter Efficiency Calculation Tool) which allows evaluation of the power output based on public available particle concentration data. That way e.FFECT allows determining the economically best filtration layout for any given power plant.

Language / Country

Language / Country