The service program for maximum dedusting efficiency

Individual complete solutions for your dust removal units

Get the most out of your dust removal unit. Put your trust in cost-efficient filter solutions from Freudenberg and Viledon filter service offering for optimizing, servicing and maintaining dust extraction systems.

Is your dust removal system not working properly?

We will work with you to find the solution

With the numerous services it offers, Viledon filter service provides the answers to your questions and problems concerning your dust removal system. We have summarized the most important ones for you below:

-

How do I optimize the extraction performance of my dust removal system?

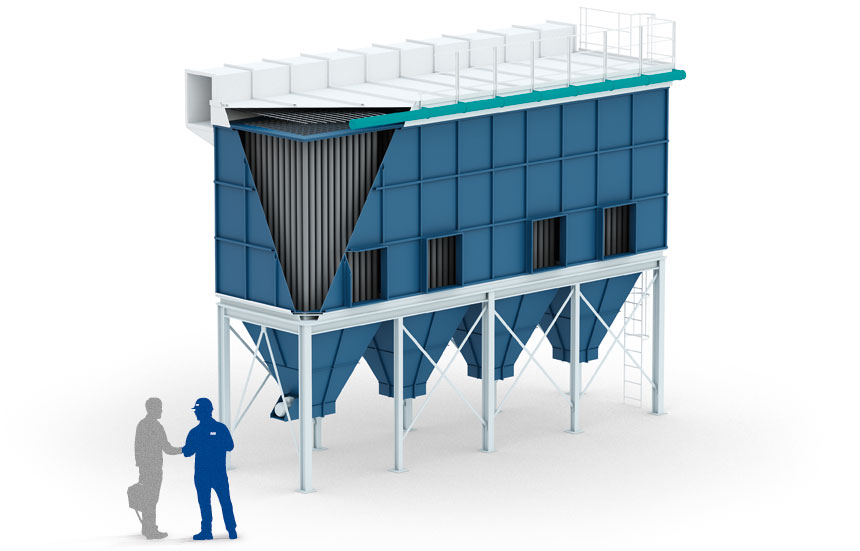

The first step towards optimization is a comprehensive check of the current condition of your dust removal system and its specific components, from the supply air duct to the exhaust air duct. Particular emphasis is placed on any pressure drops at the filter, contamination of the lines and fan performance. A volume flow measurement and energy analysis also form part of the current status analysis.

Based on the results, we are able to identify potential improvements and savings for you – for example by using new filter media with lower pressure drops or control units to improve compressed air cleaning.

-

How can I comply with my workplace and/or emission limits?

The first step is to determine your current emission values (emission analysis) in the exhaust air duct. Excessively high values indicate that filters are leaking or have leaks. We will be happy to replace the relevant components for you or recommend alternative products. If workplace limit values are exceeded, the extraction performance of the system should be checked to ensure that the health of your employees is reliably protected.

-

Are my filter elements tightly installed and is my filter system free from leaks?

If you are unsure whether all filters have been correctly installed, it is advisable to check the exhaust air values. A leakage test will indicate possible leaks. Inspecting the filters in the filter chamber during downtime can also help.

-

Who can change the filters in my dust removal system?

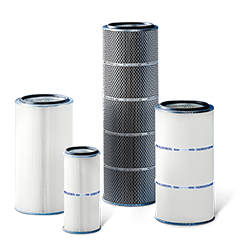

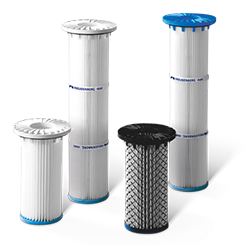

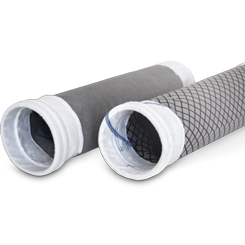

Our specialist team will be happy to assist you with a comprehensive service when changing filter elements such as plates, cartridges and bags. This not only includes changing the filters themselves, but also checking your system before and after replacement, as necessary. Depending on the individual requirements and the prevailing dust conditions, we work with you to agree suitable filter solutions and thus ensure perfect impermeability and optimum operation.

-

Why is the pressure drop of my filters so high?

There are many reasons for high pressure drops. If the filter material used is unsuitable for the prevailing dust conditions or if the cleaning of the filter elements does not function properly, this has a negative effect on the pressure drop. Improper geometry of the filter elements can also lead to high pressure drops. The comprehensive status analysis of your plant will reliably detect any such potential sources of error.

-

How can I reduce the energy consumption of my dust removal system?

An assessment of energy consumption forms part of the status analysis of your plant, in the course of which individual components are checked for their functionality. Measuring energy consumption accurately determines how much energy is currently being used.

On the basis of these values, we create individual recommendations and optimization proposals to effectively reduce energy consumption in the long term. Feel free to contact us – we will be happy to work out appropriate solutions for you.

-

How do I prepare my dust removal system for an audit?

As part of our Viledon Filter service contracts, you can have your system continuously monitored by one of our qualified service technicians. A meaningful and audit-compliant report is generated for each inspection. In addition, you can also request annual maintenance, emission value measurement or an energy analysis of your dust removal system. We individually tailor the various inspections and optimizations to the needs of your plant.

Regular inspections and services directly on site

Your complete air quality management with Viledon Filter Services

Viledon Filter services offers you individual service contracts for complete air quality management. Viledon Filter service experts carry out on-site inspections and measurements at regular intervals to ensure the optimum performance of your dust removal system. At the same time, we are always at your side with help and advice on technical questions.

As part of the monitoring and maintenance of your plant, we prepare visit reports containing all measures taken and the results of the measurements, along with detailed recommendations on what action to take for your process. Furthermore, we can also assume responsibility for the storage, disposition and stocking of the filter elements.

Rely on Viledon filter services and choose from our services the perfect solution for your needs

Your advantages at a glance

- Maximum efficiency improvement for your dust removal system

- Continuous monitoring and documentation for maximum operational dependability

- Simplified ordering processes

- Full cost control

- Viledon's filter service expertise for smoothly running dust removal processes

Viledon Filter service modules

Tailor-made service packages for your needs

With the Viledon filter service modular solutions, we offer you a comprehensive selection of application-specific services that can also be individually combined with each other.

Module FILTER CHANGE

Scope of services:

- Planning and organization of the filter change

- Supply of high-quality filter elements for emission control

- Thorough cleaning of the filter chamber

- Professional and quick replacement of filter plates, cartridges or bags

- Assessment of the system components, e.g. inspection of the support baskets

- Acceptance of the newly equipped filter system

- Disposal of used filter elements (optional)

- Supply of high-quality pre-filters and fine filters (e.g. for oil mist separation)

Module STATUS ANALYSIS

Scope of services:

- Thorough status analysis of your dust removal unit

- Examination of system components, from supply air duct to exhaust air duct

- Measurement of pressure drops

- Volumetric flow measurement

- Energetic consideration of the dust removal unit

- Identification of improvement and savings potentials (weak point analysis)

- Plant optimization

- Documentation of all performed services and analyses

- Sound recommendations for the layout of your plant

Module LEAK TEST

Scope of services:

- Reliable leak tests or impermeability tests

Module EMISSION ANALYSIS

Scope of services:

- Emission value measurement in the exhaust air duct

- Verification of compliance with emission limit values in accordance with the German Federal Immission Control Ordinance (BImSchV) and the Technical Instructions on Air Quality Control (TA Luft)

Module WORKPLACE ANALYSIS

Scope of services:

- Review of occupational limit values

- Measurement of the maximum workplace concentration

Benefit from our specialized expertise in industrial dust removal.

Select and request detailed information.

Discover our products for air pollution control.

Click details for more information. Technical data and specific product features can be found in the e-catalogue.

Ideal for simple upgrading of typical systems. Long lifespan even under extreme operating conditions. Especially effective in the separation of abrasive or chemically aggressive dusts. The service life can be extended by washing.

Special design details and the availability in all geometries customarily demanded by the market ensure efficient dust removal. Equipped with 3- or 4-hook injection molded flange, spacer ribs on both sides and centering collar.

Tool-free, easy installation on the clean air side, with no laborious screwing work. Simply press firmly and the patented snap hooks lock into place. Perfectly suited for use in suction excavators and cleaning vehicles.

Equipped with corrugated polyester filter medium and nanofiber layer. For the protection of people and machines, they achieve optimum values when dealing with fine dust and smoke. This extends the service life and improves energy balance for the system's operator.

With original Evolon® technology. Outstanding advantages over needled felt bags. 50% lighter, simple handling for cleaning and installation. For sustainably low emissions and reduced energy costs.

Master difficult dust removal tasks while complying with statutory residual dust emission values. Compact, space-saving design with pleated filter media. Regenerated via typical cleaning and washing.

Many different variants: Media with sinusoidal corrugation and patented pleat stabilization, with corrugation plus nanofiber layer or with antistatic features for high operational dependability in contact with explosive dusts.

PulseWatch

Freudenberg PulseWatch is an individually configurable device for the intelligent control and automation of compressed air cleaning in a dust removal system.

Language / Country

Language / Country