Reliably hygienic production of confectionery

With individual filtration solutions for flawless air hygiene

Confectionery production is a sensitive process that is subject to strict hygiene rules. For hygienically flawless processing of the individual steps, it is especially important to supply germ-free air. Our filtration solutions make a valuable contribution to excellent air quality.

Clean air in all areas

For maximum product quality, shelf life and profitability

Hygiene is a top priority in the production of confectionery such as chocolates and marzipan, nougat or jelly products. In addition to appropriate protective clothing, an air filter system helps reduce airborne particles to an absolute minimum. With filter combinations specially adapted to your application, Freudenberg Filtration Technologies ensures optimal air quality across all production areas: from processing of the raw materials to baking, cooling and final packaging of the treats. This protects your products from negative environmental influences and helps lower energy costs.

Benefit from our specialized expertise in confectionary production.

Select and request detailed information.

Discover our products for the confectionary production.

Click on details for more information. Technical data and specific product features can be found in the e-catalog.

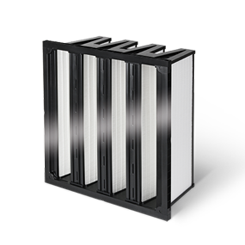

Satisfy the highest requirements for clean air and sterility of filter classes E11 to U15. Reliable protection against particles and microorganisms. The MiniPleat technology ensures a homogeneous media velocity for safe, economical operation.

The premium class in patented quality. Highly stable filter designs for the greatest possible operational dependability even under extreme loads. Water-repellent. Long service life, making them very economical.

Robust and extremely dependable in hygienic quality. With water-repelling hybrid synthetic nonwoven media (HSN) suitable for use in damp environments. Ideal for air-conditioning systems.

Optimal price-performance ratio in the operation of ventilation systems plus simple and safe handling. MVP 95 filters achieve energy efficiency class A. Energy cost savings and reduced CO2 output.

Robust in sustained use, high operational dependability and reliability even in the face of extreme moisture and wet conditions. They enable the energy-efficient operation of air conditioning systems. This translates to energy cost savings and a reduction in CO2 emissions.

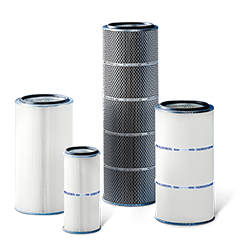

Wide selection of appropriate dust removal elements, variable in terms of shape, overall height, nominal diameter and pleat geometry. For maximized performance.

Reliable removal of contaminant gases from the supply or recirculating air. The modules are an assembly of Honeycomb (HM) media housed in either a plastic or metallic frame. Easy to install.

Want to know more about Food & Beverage Filtration or have a question?

For an audit

For your Food and Beverage Systems

SIMPLY FILL OUT THE FORM WITHOUT OBLIGATION

Language / Country

Language / Country