Corrosion protection for every challenge

Eliminate contaminant gases. Protect electronic components and processes.

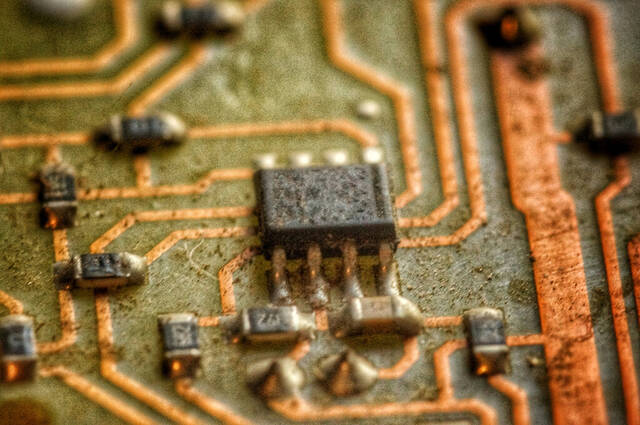

Corrosion is a electrochemical oxidation of metals which causes damage by producing oxides and salts on surfaces.

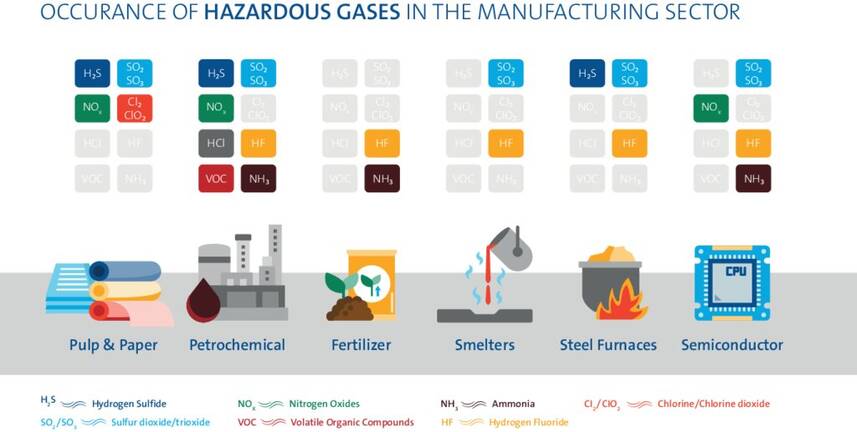

This is caused by specific corrosive gases, which evolve in certain manufacturing and chemical processes.

Corrosion protection is essential as conductivity and its resistance change in the affected electric boards and electronic circuits. This results into malfunctions, failures or damages of equipment. The consequences can be reduced process efficiency, additional maintenance expenses, costly repairs and unplanned downtimes.

Lower your costs by protecting all sensitive areas against contaminant gases and corrosive processes.

Your advantages at a glance

- Increased process dependability

- Customized filtration solutions

- Long filter lifetime

- Low energy consumption

- Supplemental services for maximum filter performance

Corrosion control thanks to gas phase filtration

Solutions from Freudenberg Filtration Technologies for sustainable process protection

Even though the problem of corrosion is nearly the same, the source varies from industry to industry. High relative humidity (> 50% rh) and high temperatures (>25 ºC / 78 ºF) can increase the corrosivity of contaminant gases. A distinction is made between acidic gases (H2S, SO2, SO3, NOx, Cl2, ClO2, HF), alkaline gases (NH3 )and oxidizing gases (O3). These gases typically affect server rooms, control rooms, motor control centers (MCC), electric substations, air compressors and offices.

Benefit from our specialized expertise in corrosion control.

Select and request detailed information.

Discover our products for corrosion control.

Technical data and specific product features can be found in the e-catalog.

Comprehensive pellets portfolio for the reliable removal of contaminant gases by means of adsorption, absorption and chemisorption. Depending on the process requirement different pellets are used.

The future of air purification technology: The special structure of the media allows a highly efficient interaction between the carbon and the air. Adaptable to specific performance requirements on site.

Rugged plastic housings that contain ChemControl Pellets for chemical filtration. Available in four sizes to equip systems for almost all applications. Easy handling and replacement.

Reliable removal of contaminant gases from the supply or recirculating air. The modules are an assembly of Honeycomb (HM) media housed in either a plastic or metallic frame. Easy to install.

Multi-stage filtration systems with ChemControl pellets for the efficient and safe removal of contaminant gases. A pre- and fine filtration also ensures optimum protection against particles.

Multi-stage filtration systems with Honeycomb (HM) modules mounted on skids. Provide highly purified makeup air for pressurizing control rooms to prevent the intrusion of contaminated air.

A maximum application flexibility with easy handling and highest cost-effectiveness. Filled with different Viledon ChemControl pellets depending on the process requirements.

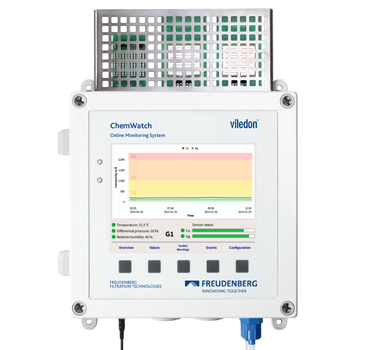

Measures and monitors the corrosivity of air in rooms via copper and silver sensors. The only online monitoring system with a large color display for clear visibility at a glance.

Language / Country

Language / Country