Corrosion control from the filtration specialist

Individual comprehensive solutions for gas phase filtration

There are numerous contaminants that can cause corrosion: acidic gases such as hydrogen sulfide, sulfur oxides and others, even ozone. With its gas phase filtration solutions and Viledon FilterCair services, Freudenberg Filtration Technologies provides effective protection for all of the sensitive areas of your processes.

How can you protect your systems permanently against corrosion caused by aggressive harmful gases?

Together with you we will analyse your process conditions and find a solution.

With its numerous modules, Viledon FilterCair provides answers to your questions about gas phase filtration and corrosion control. We have summarized the most important for you.

-

What options are there for protecting switch cabinets and control rooms against corrosion?

Acid gases can be produced during the production process. These often enter unhindered into control rooms and switch cabinets where they can cause corrosion on electronic components. To prevent corrosion damage, the control room should be pressurized to reduce or prevent the penetration of acid gases. It is also important that doors and windows in the control room are always tightly closed so that the room is sufficiently leak-proof.

A very effective solution for filtering harmful gases from the air and protecting current-carrying components against corrosion is to install a Viledon ChemControl system. As well as particle filters, the units also includes modules with Viledon ChemControl pellets (sorption media), which neutralize the incoming acidic gases. This ensures that your control room is supplied with purified air and also kept at overpressure.

We will be happy to advise you on the use of this kind of system. Our Viledon FilterCair experts are available to you throughout Germany for regular inspection and maintenance of Viledon ChemControl Systems.

-

How can I tell if there is a corrosive environment?

Do you experience sporadic failures of electronic switchgear components or have you noticed discoloration on copper or power lines during visual inspection? If so, these could be the first signs of the presence of corrosive gases in the ambient air, which could be released during your production process, for example.

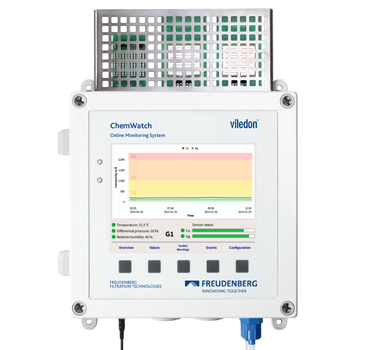

Our Viledon FilterCair experts will be happy to assist you in checking the corrosive environment in your control room. By means of a coupon test, we can measure the level of the harmful gases and work with you to determine the cause. For ongoing checks, we recommend the installation of a Viledon ChemWatch Online Monitoring System, which allows you to continuously assess the corrosiveness of the room air.

If the concentration of harmful gases in your control room is excessive, we will be happy to advise you on site about the various filtration concepts available to ensure reliable protection against corrosion.

-

What do you need to know about a room to actively protect it against corrosion?

When designing a new filtration system (e.g. a Viledon ChemControl system), the main requirement is to calculate the room volume. The air exchange rate is determined by our Viledon FilterCair experts at your site, depending on the system type (supply and exhaust air or recirculated air operation). The resulting room parameters have a decisive influence on system operation in recirculation or overpressure mode.

Furthermore, if people are permanently present in the room, we recommend that you also take the VDI 6022 guidelines into account. We would be pleased to support you in the design of your filtration system.

-

How can I ensure that my filtration system (e.g. Viledon ChemControl System) permanently maintains the corrosiveness in the room at ISA class G1 level?

To ensure a permanently clean filtration process and reliable protection against corrosion, regularly inspecting your system or the filter media used (particle filters and sorption media) is crucial. When servicing your system, we are able not just to check all system components, but also to measure the level of harmful gases (coupon test) in the room and carry out a residual service life analysis of your sorption media.

For permanent observation of the corrosiveness in your control room, we recommend the use of an online monitoring system (e.g. Viledon ChemWatch) with a defined alarm threshold. This system allows the individual ISA classes based on ISA S71.04 to be continuously and reliably checked.

We will be pleased to advise you on our services covering all aspects of gas phase filtration.

-

How can I determine the remaining service life of sorption media (e.g. Viledon ChemControl Pellets)?

The analysis of the residual lifetime of sorption media can be performed as follows:

You or our Viledon FilterCair experts take a material sample of the bulk material from the filter module being used. It is best to use an appropriate sampler for this purpose. The sample in a sampling bag is sent to our laboratory for evaluation. As soon as we have analyzed the samples, we will send you information about the remaining service life of the sorption media you are using, enabling you to plan the next media change accordingly. However, please note that it is not possible to determine the remaining service lifetime for all types of sorption media.

Our Viledon FilterCair experts will be happy to assist you in taking the samples and the subsequent analysis process. If required, you can also fully delegate the control of the sorption media as well as the replacement and maintenance of the air filter system to our service team. We look forward to receiving your enquiry.

Viledon FilterCair service

Your comprehensive service package for maximum filter performance

Improve the performance and efficiency of your gas phase filtration with the sophisticated Viledon FilterCair filter management system.

Your benefits: Reliable corrosion and odor protection with customizable packages – consisting of a comprehensive filter selection plus services and warranties at guaranteed fixed costs. Let us help you implement a high-performance and environmentally friendly system solution for your gas phase filtration to achieve a long-term reduction in your operating costs.

Viledon FilterCair service modules

Custom-tailored service package for your needs

With module solutions from Viledon FilterCair, we offer you a comprehensive selection of problem-specific services that can be individually combined.

BASIC package

Scope of services:

- Delivery of high-quality gas phase filters and modules

- Professional change-out of pellets

- Reliable module replacement

- Disposal of used pellets

- Delivery of high-quality prefilters and fine filters

COMPLETE package

Scope of services:

- All benefits of the BASIC package included

- Analysis of the current situation

- Recommendation of an optimal filtration system

- Differential pressure controls

- Determination of remaining lifetime of pellets

- Regular measurement of indoor air quality*

- Ongoing monitoring of indoor air quality*

* pursuant to ISA-71.04-1985

Supplement your BASIC or COMPLETE package with the following optional modules:

Module ENERGY EFFICIENCY

Scope of services:

- Air handling consulting,incl. air flow balance sheets

- Energy efficiency consulting for HVAC systems

- Energy inspection of your equipment according to §12 EnEV

Module HYGIENE INSPECTION

Scope of services:

- Microbiological assessment of water samples (bioburden)

- Hygiene inspection of ventilation systems according to VDI 6022

We’ll be pleased to advise you. Talk to us. Together, we will find the package that suits you, or the individual solution that is right for your specific application.

Benefit from our specialized expertise for reliable corrosion control.

Select and request detailed information.

Discover our products for gas phase filtration.

Click details for more information. Technical data and specific product features can be found in the e-catalogue.

Comprehensive pellets portfolio for the reliable removal of contaminant gases by means of adsorption, absorption and chemisorption. Depending on the process requirement different pellets are used.

The future of air purification technology: The special structure of the media allows a highly efficient interaction between the carbon and the air. Adaptable to specific performance requirements on site.

Rugged plastic housings that contain ChemControl Pellets for chemical filtration. Available in four sizes to equip systems for almost all applications. Easy handling and replacement.

Reliable removal of contaminant gases from the supply or recirculating air. The modules are an assembly of Honeycomb (HM) media housed in either a plastic or metallic frame. Easy to install.

Multi-stage filtration systems with ChemControl pellets for the efficient and safe removal of contaminant gases. A pre- and fine filtration also ensures optimum protection against particles.

Multi-stage filtration systems with Honeycomb (HM) modules mounted on skids. Provide highly purified makeup air for pressurizing control rooms to prevent the intrusion of contaminated air.

A maximum application flexibility with easy handling and highest cost-effectiveness. Filled with different Viledon ChemControl pellets depending on the process requirements.

Measures and monitors the corrosivity of air in rooms via copper and silver sensors. The only online monitoring system with a large color display for clear visibility at a glance.

Language / Country

Language / Country