Filter efficiency calculation with e.FFECT

Find your filtration solution – digitally optimized

Standardized systems for supply air and intake air filtration are often inefficient and do not make full use of optimization potential. The more precisely filter systems are tailored to their respective environmental conditions and plant requirements, the more performance-optimized, safe and energy-efficient they are.

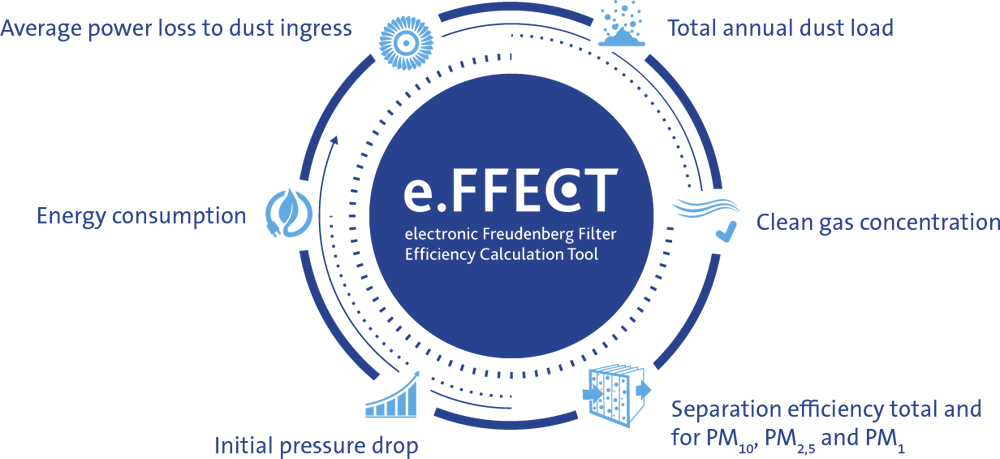

This is where e.FFECT comes in, the electronic Freudenberg Filter Efficiency Calculation Tool. This software tool depicts the real situation in a digital model and facilitates the performance analysis of single-stage and multi-stage filter systems.

Mapping reality

Different ambient air conditions

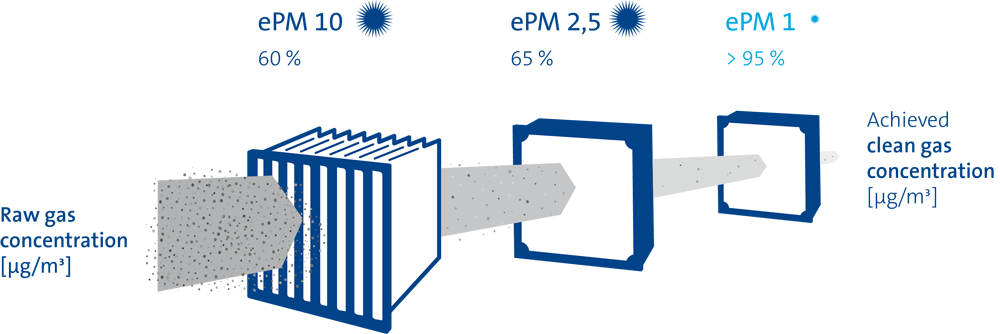

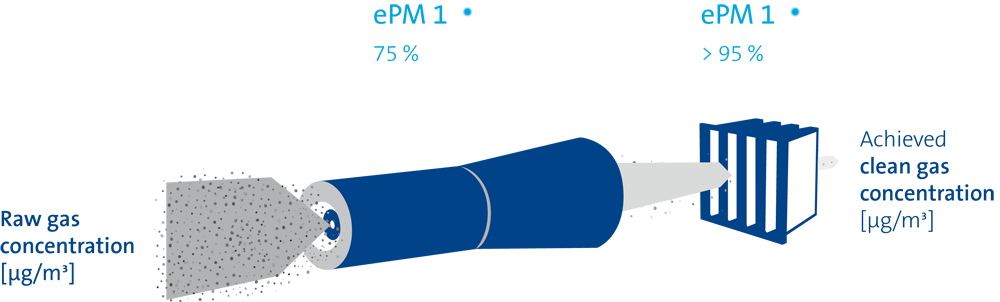

The program calculates individual separation efficiency for the PM1, PM2,5 and PM10 fine dust fractions, the deposited dust quantities and other parameters for filter stages in sequential configuration. The calculation is based on site-specific ambient air concentrations of particulate matter and process-relevant variables, such as annual running time and volume flows. As a result, e.FFECT complies with all requirements of the ISO 16890 filter test standard, which has been in force since mid-2018.

SITE-SPECIFIC ENVIRONMENTAL CONDITION + PROCESS-RELEVANT REQUIREMENT = EFFICIENT FILTRATION SOLUTION

Six relevant values at a glance

Choose your calculation parameters

Your benefits

e.FFECT enables you to find the optimum filtration solution

- Location- and plant-optimized filtration solution

- Full transparency and comparability thanks to structured calculation protocol and final report

- Reduced downtime and lower plant maintenance costs

- Reduced total costs of ownership (TCO) thanks to individually optimized solutions

- Improved economic efficiency

- Safe production processes

Ask the filtration specialists, to formulate your needs and together we can decide on the degree of purity of your individual air intake system.

Gas turbines and compressors

Food & Beverage, Industrial Painting, HVAC

Language / Country

Language / Country