Air hygiene – A recipe for success

Rügenwalder Mühle places its trust in Viledon FilterCair

Rügenwalder Mühle has been producing high-quality food since 1832. To this end, the long-established brand focuses on modern production processes with the highest hygiene standards – including when it comes to air filtration. Thanks to the Viledon FilterCair service package, the company is able to ensure that clean air is permanently available in its production areas.

Among other things, the quality of food depends on the hygiene conditions during production. If bacteria, fungal spores or other impurities penetrate the production process, this has serious consequences. Optimum processing conditions in accordance with strict hygiene regulations are absolutely essential to ensure that consumers can rely on the quality of Rügenwalder Mühle products at all times.

A customized service package

Alongside uncompromising air purity, the company has focused particularly on increasing filter service life. This is because every filter change interrupts the production process and reduces cost-effectiveness. The company was keen to ensure reliable and economical plant operation with filters that were as long-lasting as possible. Against this background, Rügenwalder Mühle worked together with Freudenberg to develop an individual Viledon FilterCair service package aimed at achieving maximum hygiene, long-term operational reliability and greater reduced costs.

Adapted to on-site conditions

The comprehensive Viledon FilterCair service package is designed to meet the demanding hygiene requirements of the food industry. It has also been specially tailored to the two-stage filter system installed in the factory, with T 60 pocket filters as prefilter stage and MaxiPleat MX 98 cassette filters as fine filters. This means that, in addition to regular monitoring of the filter and ventilation elements, specialists also carry out hygiene inspections according to strict industry criteria. Weak point analyses are also proactively carried out, enabling optimization potentials to be promptly identified and exploited.

Continuous analyses and documentation

For Rügenwalder, intensive contact with Viledon FilterCair technicians is particularly important. They are regularly active at the factory and provide support in all matters relating to air quality. Transparency also creates trust: All inspections, analyses and services are fully documented in accordance with auditing requirements. This ensures legal certainty and reduces administrative costs. Viledon FilterCair also advises on energy efficiency measures to ensure optimum use of resources and minimize costs.

Fewer filter changes, more economical production

The result is very much to the taste of Rügenwalder Mühle: with the newly established filter system, filter service life has been significantly increased. Where it used to be necessary to change filters every year, the filter elements can now be used for much longer. This means that production is interrupted less frequently and is therefore more economical and reliable. The energy-efficient Viledon filters are one part of this success. Thanks to low pressure drops, they save a great deal of energy. Franz Gottwald GmbH + Co KG – a long-standing commercial partner of Freudenberg – is responsible for the storage and logistics of the filters. The overall benefit of this cooperation for Rügenwalder Mühle is greater process reliability and lower operating costs.

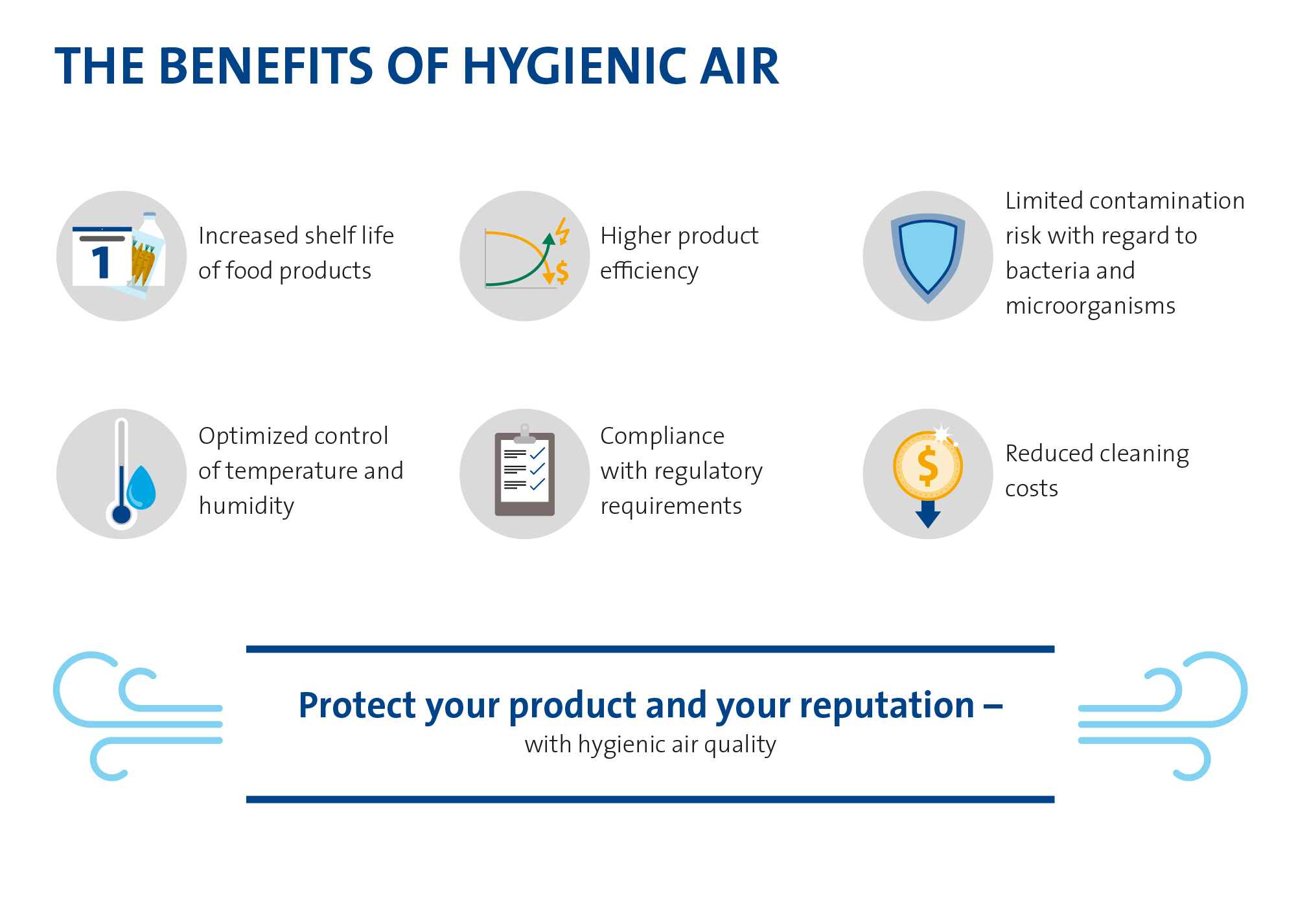

Die benefits of hygienic air

Language / Country

Language / Country