Dry separation made easy

At the PaintExpo in Karlsruhe, Freudenberg Filtration Technologies presented modern filtration solutions for the dry separation of overspray in paint shops. At the PaintExpo in Karlsruhe, Freudenberg Filtration Technologies presented modern filtration solutions for the dry separation of overspray in paint shops.

Dry paint mist separation in paint shops is very much in vogue. This trend has been given a further boost by the new version of the Federal Pollution Control Regulation from 2017 (42. BImSchV), which places even tougher requirements on wet leaching systems. At PaintExpo 2018 in Karlsruhe from April 17-20, the leading international trade fair for industrial coating technology, Freudenberg Filtration Technologies will be presenting the alternative: dry separation using modern filtration solutions. Using neither water nor chemicals, this system is effective, efficient and easy to handle. Freudenberg technicians and engineers will be on hand to explain how easy it is to switch from wet to dry separation. The company will also be focusing on another key theme: Viledon FilterCair modules, the holistic filter management system from Freudenberg Filtration Technologies.

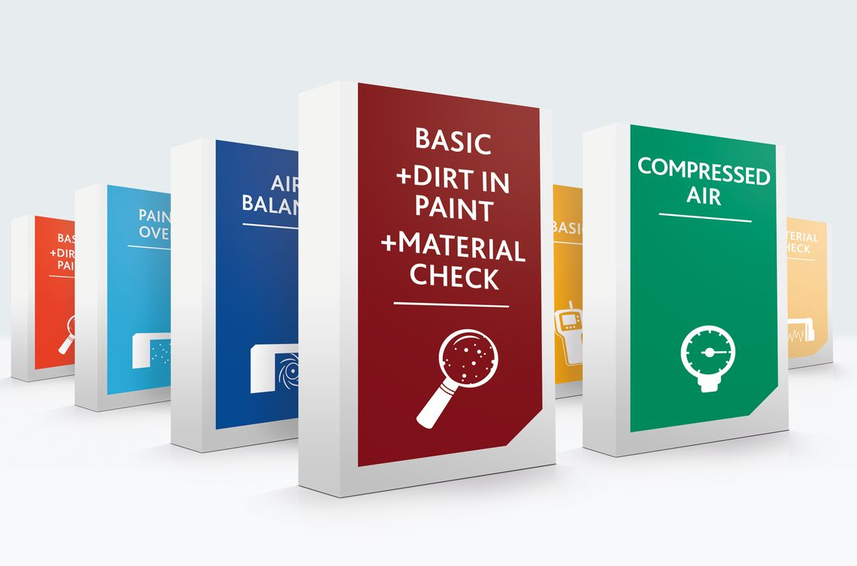

Viledon filterCair modules: Customized service packages for your needs

Viledon filterCair modules: Customized service packages for your needs

Easy-to-handle boxes made of fire-retardant corrugated cardboard

Ingeniously simple, simply ingenious. Few products are more worthy of this description than edrizzi paint mist separators. The easy-to-handle boxes are made of fire-retardant corrugated cardboard. The intricate composition of their internal structure gives them an enormous overspray absorption capacity and achieves a filtration efficiency of up to 97 percent. Another advantage is that they can be cheaply disposed of by incineration. In short, the edrizzi filter boxes make switching from wet to dry separation both easy and profitable. The cost of conversion will be recouped in quick time. Freudenberg Filtration Technologies will be providing details and background information at PaintExpo. The company will also be showcasing their new DryPleat filter plate series with nanotechnology. The products enable process-safe and particularly energy-efficient dry separation of paint overspray using stone powder. They also contribute to a sustainable reduction in the operating costs of paint shops.

Viledon FilterCair

Viledon FilterCair from Freudenberg encompasses all factors that influence and improve the painting process from a qualitative and economic point of view. Viledon FilterCair now also offers its expertise in process analysis and optimization, outside the scope of fixed service contracts - regardless of whether a customer uses Viledon filters in their paint shop or not. For optimum air quality management, plant operators can select from seven modules, all of which can be freely combined as needed. This holistic approach makes processes more efficient, which in turn saves operators time and money and improves coating results. Visitors to the Freudenberg stand in Hall 2 (Stand 2630) will be able to look through a microscope to get a first-hand practical impression of this.

Language / Country

Language / Country