Hygienic Air Quality for the Dairy Production Industry

Reliably hygienic production of dairy products relies on effective contamination control with individual food safe certified filtration solutions for flawless air hygiene

The Dairy production of milk products like butter and buttermilk, cheese, fermented milk products, curds and whey are subject to strict hygiene regulations and requirements for food production safety. This poses numerous challenges, in achieving an appropriate level of air hygiene. Controlling air quality and air change rates, together with temperature and humidity levels, in cleanrooms and filling halls all play a key role in contamination control.

Hygienically pure air, optimized by Freudenberg Filtration for your dairy production needs are Complete solutions that meet or exceed the strictest Hygiene requirements. The ideal filtration solution must always take into account your individual dairy process requirements. To this end, Freudenberg Filtration works with you to evaluate your current dairy ventilation system and identify recommendations for the design, installation and maintenance of an optimal Hygienic Air filtration solution.

Freudenberg Filtration Technologies in HEPA filters Satisfy the highest requirements for clean air and sterility of filter classes E11 to U15 "Efficient for particles ≥ 0,01 μm". Reliable protection against particles and microorganisms. The MiniPleat technology ensures a homogeneous media velocity for safe, economical operation.

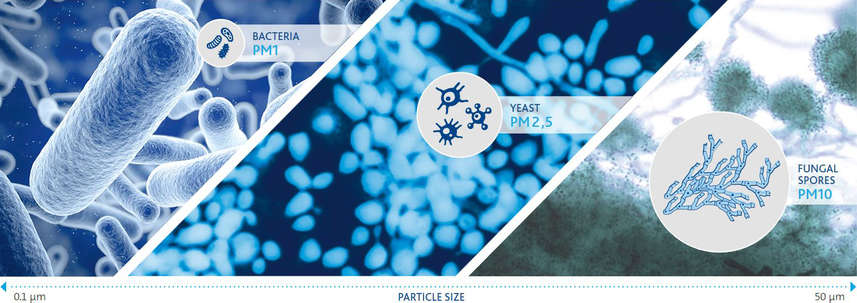

Exemplary particle classification to Particulate Matter fractions for food and beverage production.

Exemplary particle classification to Particulate Matter fractions for food and beverage production.

Maximum safety and protection for highly sensitive dairy products using Complete Hygienic Air Quality solutions for strictest dairy Hygiene requirements

. Milk filling

Consistently controlled air quality in the Dairy Production milk filling hall or cleanroom prevents the build-up of microorganisms presence and increases the shelf life of the products. Aseptic filling lines must also be equipped with efficient, high-performance filters to completely eliminate pathogens and reliably protect your products. Freudenberg Filtration Technologies supplies reliable hygienic air food safe certified filtration solutions for all your milk filling requirements.

. Milk powder/infant formula

The production of highly sensitive Dairy products such as infant formula demands filtration systems of the highest reliability, quality and efficiency. This applies to both the process air filtration and the ventilation systems in the process areas. Air contamination monitoring is another indispensable measure for the protection of the milk powder. We assess the production situation at your site to identify the optimal filtration system for you.

. Yogurt / cream / ice cream

Dairy Production of fermented milk products, curd, whey, cream, ice cream. In the production of these Dairy products, the more sterile the processing, the higher the quality and the longer the shelf life. To avoid microorganism and particle contamination, it is essential to monitor the air quality and air exchange together with the temperature and humidity in the filling hall or cleanroom.

. Butter and spreads

Achieve the highest quality in the Dairy production of butter, cream and spreads. A filtration system individually adapted to your needs offers optimal protection and, together with reliable temperature and air movement control, minimizes the contamination risk.

. Cheese

Cheese production is an art in itself, and the production and processing present as many challenges are there are types of cheese. The packaging of cheese is also associated with a high level of risk. All individual areas must be optimally protected and safeguarded with highly efficient filter solutions. The production of soft cheese, in particular, demands the greatest care in achieving a controlled air quality to ensure the product shelf life.

Request a Site Audit for Hygienic Air in the food and beverage industry

Food-Safe Certified Filters for Dairy Production

Under the Viledon® brand, Freudenberg Filtration Technologies offers top-quality, highly reliable filtration products to meet every need within the food and beverage industry. Viledon filters are food-safe our certificates document fulfilment of the regulations that apply to the respective filter tests.

Achieving maximum Dairy air filtration reliability

Our multi-stage filter concept is both simple and efficient: well-matched filter stages using Viledon® air filters of various classes and designs. This usually involves two-stage pre-filtration

Viledon® air filters for pre-filtration

Viledon® offers a comprehensive air filter program of filter classes G 4 to F 9 for our food-safe certificated pre-filtration systems

Viledon® air filters for the finest hygienic Dairy air filtration

Viledon® EPA, HEPA and ULPA meet the toughest clean-air and sterility, food-safe certificated requirements

You can benefit from the Freudenberg expertise now!

Learn more about Optimum hygienic safety in food and beverage production

Freudenberg Filtration Technologies | Microfresh® Diesel Particulate Nanoparticle Filter Solutions Australia.

Language / Country

Language / Country