Despite the elements

Two Thai gas and steam turbine power plants profit from reliable filtration solutions for tropical conditions.

Turbines in power plants depend on reliable filtration of the supply air. Inadequate filters, which allow dirt and moisture to pass through, endanger process reliability. If turbines fail, this quickly leads to bottlenecks in the power supply. Filter solutions from Freudenberg Filtration Technologies are making two power plants in Ratchaburi, Thailand, both more reliable and more powerful.

Between May and October, conditions are particularly oppressive. Rarely does the temperature fall below 30 °C and it rains almost daily. The humidity is noticeably high, usually over 80 percent. Filters without permanent moisture protection quickly lose their separation efficiency under these conditions and wear out faster. As a result, the penetrating moisture can pollute the machines and damage them to such an extent that the operational safety and process stability of the systems are endangered.

High loss of power causes problems

The two power plants in Ratchaburi generate electricity for the region. The turbines they use to do this need to be able to cope with the effects of climatic conditions. Previous filtration systems did little to help and had to be replaced after less than a year of running time. The turbine blades fouled quickly and became increasingly inefficient due to low and decreasing filtration performance over time. Unplanned maintenance and downtime as well as frequent filter changes were the result.

Supply air filter houses of the power plant in Ratchaburi

Supply air filter houses of the power plant in Ratchaburi

The solution: systematic moisture protection

With the aim of reliably protecting the turbines at the two power plants against the demanding climatic conditions over the long term, our experts worked with the power plant operator to devise the optimal solution. 800 and 672 sets respectively of Viledon® GTS Pulse-Jet filter cartridges of filter class F 9 / ISO ePM1 80 % replaced the previously installed filters. Each cartridge is wrapped with a synthetic-organic filter material. This serves as a coalescer and protects the filters and turbines against excessive moisture and penetrating water. Coarse dirt particles are also trapped by the protection.

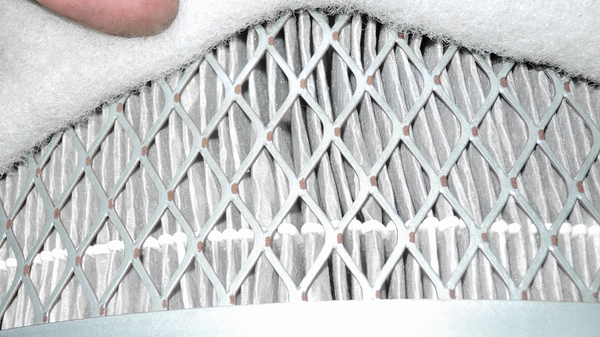

Viledon GTS filter cartridges with nonwoven wrapping

Viledon GTS filter cartridges with nonwoven wrapping

Cartridges from Freudenberg Filtration Technologies provide reliable protection

Cartridges from Freudenberg Filtration Technologies provide reliable protection

More power, less downtime

The operator is highly satisfied with the result. While the previously used filters had to be replaced in the rainy season after only three months, the filter cartridges from Freudenberg Filtration Technologies are still providing reliable protection after two years. The water-repellent material of the Viledon® GTS filter cartridges is particularly suitable for local conditions with high humidity. The pollution rate of the turbines has been significantly reduced, which positively influences the efficiency of the compressor as well as fuel consumption. All in all, Freudenberg Filtration Technologies has thus realized a filtration solution that is optimally geared to the local climatic conditions, offers impressively long lifecycles and protects the plant safely and reliably.

Language / Country

Language / Country