German VDI 6022 revised:

scope of application limited

Where does the directive apply and where does it not?

Optimum protection for people and machinery

For many years, the German VDI Guideline 6022 applied without restriction to the planning, operation and maintenance of air filter systems in surface treatment. This is about to change because ever-stricter hygiene requirements are dominating the regulation and operators will have to differentiate more strongly.

As standard practice, VDI 6022 is applied to the air filtration of surface technology equipment such as paint shops. The recommendations of the Association of German Engineers (VDI) define hygiene and room air quality requirements for ventilation and air-conditioning systems. Amendments to the guidelines now make a distinction between ventilation and process-air systems, which are both necessary and sensible for many operators in several respects.

Ventilation and air-conditioning systems vs. process-air systems

In the case of ventilation and air-conditioning systems, the protection of people and their health is the main focus. It must be possible to enter the system at any time and find that the air quality is conducive to health. This is always the case when employees spend long periods in the plant, for example during the pre- and final assembly of vehicle parts. In contrast, process-air systems are designed for maximum process reliability. Air filtration is optimized in terms of process requirements, whereby health aspects play a secondary role. This is the case with automated painting lines or paint dryers, for example.

Protection of people and health

In ventilation and air-conditioning systems, the further development of VDI 6022 will ensure greater safety. In some cases, the requirements for hygienic supply air quality are even stricter. This is intended to ensure that contamination by harmful substances and microorganisms is prevented to the greatest possible extent. The means to achieve that goal involves individually adapted filtration concepts and mandatory regular air filter changes. In this context, the potential service life of the filters depends heavily on the outside air, supply air conditions, and the quality of the circulating air.

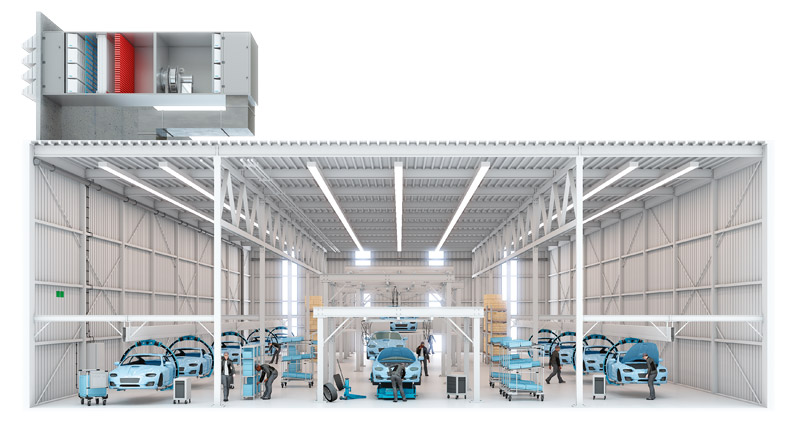

Final assembly in automotive plant with customized ventilation system

Final assembly in automotive plant with customized ventilation system

Customized filter concepts reduce operating costs

Provided that they are correctly installed, air filters in air handling systems protect the health of both employees and equipment. Filter elements with high inherent rigidity make it easier to comply with hygiene regulations, as they prevent filter pockets from touching each other or the floor. This type of surface contact promotes moisture penetration of the material and leads to contamination, which could make the filter itself a source of germs. Important: Assuming that the specifications are observed, service life can be extended by means of a risk analysis, thus saving operating costs.

However, with regard to paint shops and surface treatment, the applicability of VDI 6022 often needs to be put into context. Among other reasons, this is because process control systems can be operated much more energy-efficiently and sustainably with appropriate filter concepts – while still providing maximum process protection.

Language / Country

Language / Country