No chance for legionella

Dry instead of wet: operators of paint shops play it safe when they choose dry separation of overspray for their facilities.

“There is no reason to be alarmist”, said Jürgen Becker, who is globally responsible for surface treatment at Freudenberg Filtration Technologies. Nevertheless, the new version of the Federal Emission Control Act (42nd BImSchV) is causing paint shop operators to fundamentally review their existing exhaust air treatment systems. If wet separators are used to separate the paint overspray, the amendment to the regulations will require stricter inspection and documentation to be carried out. Wet separation systems must now be designed in such a way that they exclude any contamination of the environment by Legionella via the exhaust air.

edrizzi- dry separators

edrizzi- dry separators

A legally compliant, technically effective and economically efficient alternative is dry paint separation, for example using edrizzi® paint mist separators from Freudenberg Filtration Technologies. For smaller spray booths, the handy boxes are the first choice anyway. Thanks to new concepts from various plant manufacturers, this now also applies to large, permanently high-capacity plants. To enable risk-free testing, Freudenberg Filtration Technologies will install individually designed demonstration systems directly at the customer’s plant, without having to uninstall the existing wet separation system beforehand. This service is offered in collaboration with renowned plant manufacturers.

Caused by Legionella infection, Legionnaire’s disease can be fatal in humans. The pathogen is a waterborne bacterium. The source of infection is often the moist and droplet-laden exhaust air from cooling towers, recooling plants or wet separators. For this reason, the 42nd Ordinance to the Federal Emission Control Act seeks to minimize the risk of infection by microorganisms as much as possible.

“Wet separation plants are well established in the industry. They allow stationary operation with constant process parameters”, Becker explained. However, these systems have a number of serious disadvantages, including considerable investment and operating costs as well as high energy consumption due to pressure drops. In addition, the environmental impact of water consumption, coagulation chemicals and the costly disposal of paint sludge all have a negative impact. Not to mention the noise and odor nuisance suffered by employees involved in the painting process, as well as the corrosion problem.

Added to this are the hygiene challenges and health risks already mentioned. In the context of the current amendment to the Act, these risks necessitate considerable additional effort and costs for the operators. Particularly risky are systems with heat recovery systems, in which a suspected bacterial contamination of the water can be transferred to the supply air. An effect that has even gone unnoticed in the current revision of the Emission Control Act.

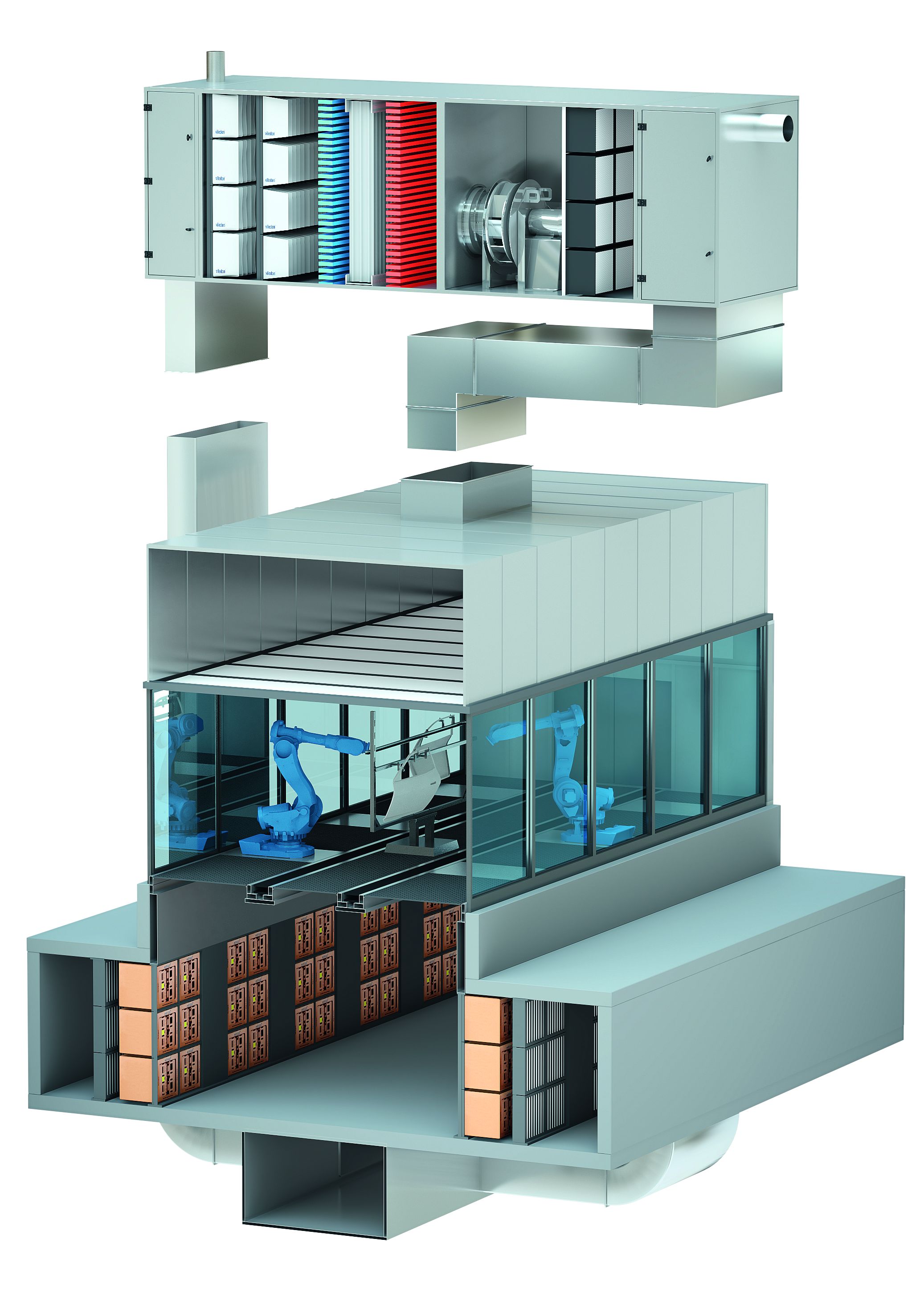

Example paint plant with edrizzi dry separators

Example paint plant with edrizzi dry separators

The legally compliant, hygienically clean and resource-saving alternative is “dry instead of wet”. Dry separation of the overspray without using water at all is suitable for new investments as well as for conversions of existing plants. This applies equally to smaller installations as well as to large, high-capacity paint plants in the automotive industry.

High separation efficiency of up to 97 percent

An ingeniously simple solution is offered by edrizzi® paint mist separators made of fire-retardant corrugated board from Freudenberg Filtration Technologies. Their intricate internal design gives them an enormous overspray absorption capacity, achieving separation efficiency of up to 97 percent together with a long service life. In addition, they can be disposed of inexpensively and in an environmentally friendly manner via incineration. Depending on the paint and requirement profile, six different edrizzi® variants are available.

Up to now, some operators have been put off using dry separation because of the need to regularly change the filters. “We have developed solutions so that this change can take place during operation and without system downtime. Handling the edrizzi® paint mist separators is child’s play anyway and they have a long service life too”, Becker added.

“With Viledon® Viledon FilterCair, we have many years of experience in process analysis and optimization in the filter management of paint shops. We systematically examine all factors that influence the painting process from a qualitative and economic point of view. This analysis then forms the basis for conceptualizing and designing an optimal filtration solution”, explained Becker.

To be on the safe side when switching from wet to dry, Freudenberg Filtration Technologies offers paint shop operators a risk-free trial run without having to uninstall the existing wet separation system beforehand. This service is offered in collaboration with renowned plant manufacturers.

Language / Country

Language / Country