Learn about the Freudenberg Pressurisation systems for silicosis prevention

Freudenberg Pressurisation systems and silicosis prevention

Approximately 2.3 million + workers are exposed to respirable crystalline silica (RCS) in the workplace, including 2 million + workers in construction and > 300,000 workers in general industry, maritime and hydraulic fracturing.

Silicosis is a lung disease caused by inhalation of crystalline silica dust.

See Worksafe Australia article on Silica in the work place

Chronic inhalation of such respirable crystalline silica (RCS) dust can lead to severe lung disease, such as silicosis or lung cancer. Having silicosis can, in turn, increase the risk of developing tuberculosis. RCS exposure has also been linked to kidney and auto-immune diseases.

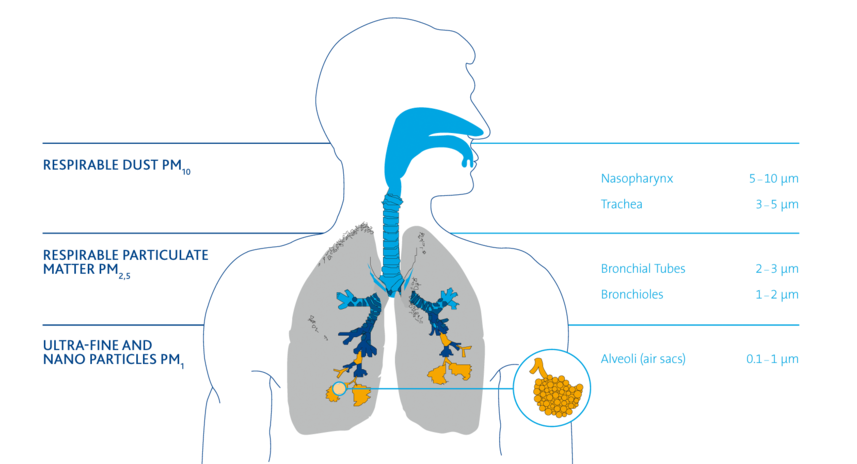

These dust particles, mostly 10 microns in size and smaller, are too small to see. When silica dust particles are inhaled, they can embed themselves deeply into the tiny alveolar sacs and ducts in the lung. The lungs cannot clear out the dust by mucous or coughing.

Silica, or silicon dioxide (SiO2) is a mineral that occurs naturally in crystalline or non-crystalline form.

Silica is the second most common element in the earth’s crust (after oxygen) and is the most abundant crystalline form is α-quartz, which is the most common mineral on earth’s continents. Found in sand, rocks (granite, sandstone, gneiss and slate), mineral ores such as quartz, soil, mortar, plaster, clay and shingles.

Industries and Commercial segments at risk of dust causing silicosis

Exposure to this dust is common in mine sites, foundries, quarries, cement/concrete works, paving and surfacing, tunneling, construction and glass manufacturing amongst others due to the excavation, earth moving, cutting, crushing, drilling, grinding or abrasive blasting activities that take place in these sites.

What Jobs are at Risk for Increased Exposure to respirable crystalline silica "RCS" dust causing silicosis?

There are risks for inhalation of respirable crystalline silica "RCS" dust causing silicosis in many jobs in many different industries.

Some examples are:

Unfortunately, there is no specific treatment for silicosis. Prevention is therefore key.

One of the best ways to prevent silicosis is to prevent the exposure to silica dust by eliminating or controlling the dust in the environments that are commonly or sporadically occupied by operators/staff.

These can be control rooms, switch rooms, substations, offices, crib rooms, transportable’s, dongas, etc. The current workplace exposure standard for respirable crystalline silica that must not be exceeded is 0.1mg/m3 (eight hours weighted average).

So how can Freudenberg pressurization units help in the prevention of silicosis?

Freudenberg have developed a range of affordable pressurization units that are a proven way to protect your employees that work in dusty environments.

Isolation of the silicosis hazard

See the Freudenberg Equipment Pressurisation Filtration Units Range to help in silicosis prevention

The concept "isolation of the silicosis hazard":

Our units are sized to work in the room of your choice. They filter the ambient air outside of the room and supplies clean air into the room. As the supply air volume is always higher than the exhaust volume (through leaks, etc), the room will always be under positive pressure. Any foreign contaminant will therefore be unable to enter the room. This will keep the dust outside of the room.

Benefits:

Helps increase protection against airborne particles that may cause

No matter where your operation is whether it be underground mining or enclosed confined space Operations Freudenberg Filtration Technologies have you breathing easier.

You can benefit from the Freudenberg expertise now!

Learn more about Diesel Particulate Filters for Coal Mining

Learn more about Disposable Diesel Exhaust Nanoparticle Filters for Coal Mining

Freudenberg Filtration Technologies | Microfresh® Diesel Particulate Nanoparticle Filter Solutions Australia.

Language / Country

Language / Country