Discover our solutions for the painting industry

Benefit from Freudenberg expertise now

Filters + Service + Consulting = Viledon FilterCair

Optimize your painting process!

Viledon FilterCair is a customer-tailored service package to meet your individual filtration and painting needs. It consists of a comprehensive range of filters plus services plus problem-specific consulting by our Viledon FilterCair specialists at guaranteed fixed costs.

Your painting process is subjected to a full analysis to determine the cause of paint damage. The focus lies on optimization of your process with regard to errors and return rates, increasing the system availability and lowering your operating costs.

Trust in Viledon FilterCair and choose exactly the right solution for your needs from our extensive range of services.

Viledon FilterCair modules

Customized service packages for your needs

With module solutions from Viledon FilterCair, we offer you a comprehensive selection of problem-specific services that can be individually combined.

Your advantages at a glance

- Comprehensive, problem-specific service packages

- Ability to combine individual service modules

- Status analysis and detailed recommendations for action by our Viledon FilterCair experts

- Comprehensive, interactive and audit-relevant measurement reports

- Individual on-site advice

Included in all Viledon FilterCair modules

Scope

- Comprehensive interactive report

- Individual optimization potentials

- Expert on-site advice

Module BASIC

Status analysis paint zone

Demonstration of quality-relevant contamination in the painting process.

Scope

- Particle measurement with laser particle counter

- Raster measurement of the settling rate in a zone

- Determination of the booth balance

- Temperature and moisture measurement

- Inspection of the pressure difference of all relevant filter stages

- Careful filter analysis and assessment

- Precise analysis of weaknesses

Module BASIC + DIRT IN PAINT

Intensive dirt analysis

Process-specific paint damage analysis – root cause analysis of contaminants in the painting process.

Scope

- Includes full range of Module BASIC features

- Extensive ProSim particle measurement

- Raster measurement of down draughts in a complete painting line

- Needs-based incident light microscopy

- Problem-specific scanning electronic microscopy (SEM/EDX) or infrared microscopy (FTIR) analysis in the Viledon laboratory

- Extensive airflow determination of all process-relevant areas

- Local dirt analysis

Module MATERIAL CHECK

Operating material analysis

Testing of fiber/ lint released by the materials and clothing used.

Scope

- Application-specific material testing

- Needs-based incident light microscopy

- Lint testing

- Accurate analysis of weak points

Module BASIC + DIRT IN PAINT + MATERIAL CHECK

Intensive dirt analysis including comprehensive extensive materials analysis

Holistic consideration of the painting process – investigation of complex system interrelations between process parameters, materials used and dirt entry. Definition of individual optimization potentials via extensive paint defect analysis.

Scope

Complete range of services from the modules Basic + Dirt in Paint + Material Check

Module AIR BALANCE

Determination of cabin balance

Examination and visualization of the flow conditions in the painting plant.

Scope

- Raster measurement of down draughts in a zone

- Temperature and humidity measurement

- Checking the pressure drop of all relevant filter stages

- Airflow determination of all process-relevant areas

- Fog test for the visualization of the flow conditions

- Careful filter analysis and evaluation

- Accurate analysis of weak points

Module COMPRESSED AIR

Compressed air check

Control of process and breathing air systems.

Scope

- Comprehensive compressed air measurement (CO, CO₂, moisture content, oil content)

- Checking the compressed air quality for contamination

- Detailed optical microscopy of the particles

- Accurate analysis of weak points

Module PAINT OVEN

Temperature curves in paint dryers

Checking the temperature profile in the paint dryer.

Scope

- Thermographic analysis via infrared camera

- Determination of the air balance in the paint dryer

- Determination of the object temperatures with temperature data loggers

- Checking the pressure drop of all relevant filter stages

- Careful analysis of HT filters

How efficient is your filtration system?

Find the optimal filter solution for your plant with e.FFECT based on ISO 16890

Standardized systems for intake air filtration are frequently inefficient and do not make full use of their potential for optimization. The more specifically filter systems are customized to the respective ambient conditions and plant requirements, the greater performance and reliability they achieve.Our experts work with you to develop the best filter solution for your plant on the basis of the testing standard ISO 16890. In the filter evaluation, typical urban and rural particle size distributions are considered based on the particulate matter fractions PM1, PM2,5 and PM10, and filter arrestance efficiencies are determined accordingly.Standardized systems for intake air filtration are frequently inefficient and do not make full use of the optimization potential. The more specifically filter systems are customized to the respective ambient conditions and plant requirements, the greater performance and reliability they achieve.

Our experts work with you to develop the best filter solution for your plant on the basis of the testing standard ISO 16890. In the filter evaluation, typical urban and rural particle size distributions are considered based on the particulate matter fractions PM1, PM2,5 and PM10, and filter arrestance efficiencies are determined accordingly.

With e.FFECT, the electronic Freudenberg Filter Efficiency Calculation Tool, calculating the optimal filter solution is extremely simple. The local ambient conditions and specific process requirements enter directly into the calculation. Filter systems can then be objectively compared. This simplifies the selection of the best filter concept for your needs.

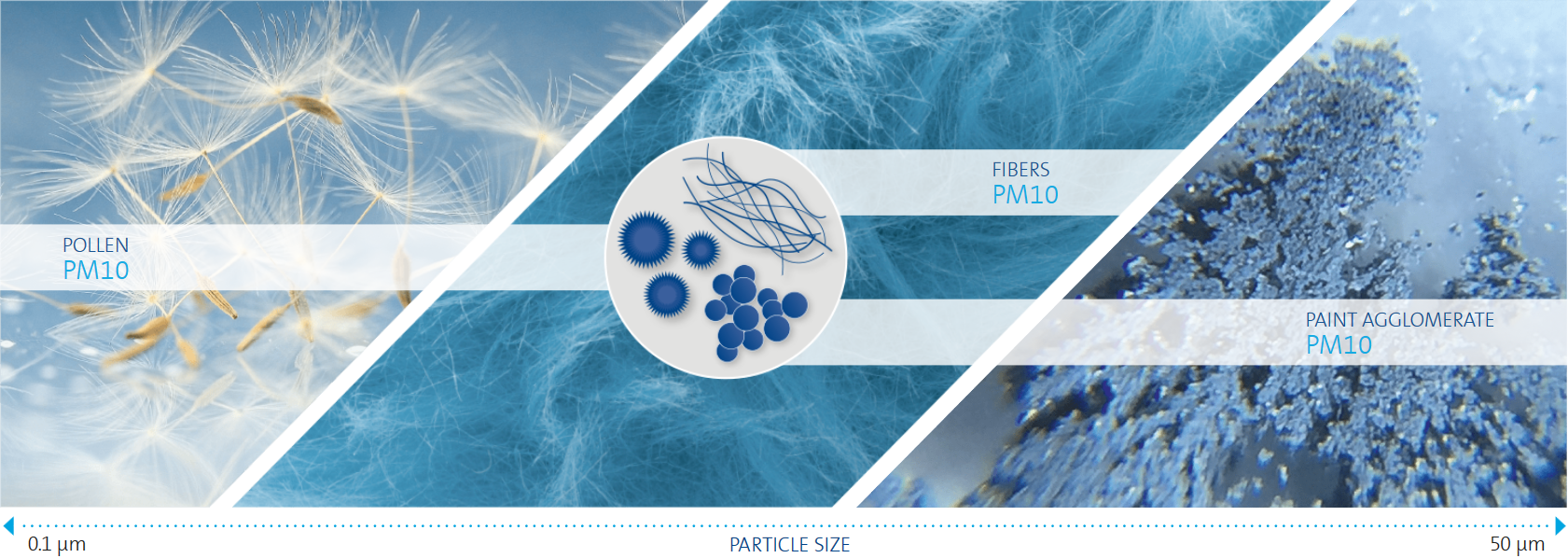

Exemplary particle consideration of PM10 fraction for industrial painting

Exemplary particle consideration of PM10 fraction for industrial painting

EUROVENT certifications

Fine filter certification

The independent institute EUROVENT Certification has developed an international certification program for fine filters of groups M and F that is currently being revised on the basis of ISO 16890. All Viledon fine filters are certified by EUROVENT.

Energy efficiency classes

EUROVENT, the European association of manufacturers of drying and HVAC systems, has developed a classification system for the energy efficiency of air filters. Your advantages: Energy-efficient filters can be identified at a glance.

In our download area, you will find detailed information about our technologies.

Viledon filter systems for the paint spraying industry

Cost-cutting filtration systems for glittering results in the paint spraying industry

Benefit from our specialized expertise in industrial painting.

Select and request detailed information.

Discover our products for industrial painting.

Click on details for more information. Technical data and specific product features can be found in the e-catalog.

Efficient filtration of paint mist in the painting process. Maximum process reliability through long lifetime and high paint storage capacity.

Thanks to their outstanding filtration characteristics they enable a significant improvement in process stability and a sustained reduction in operating costs.

High-quality material structure and a high shape stability for a maximum efficiency in paint mist separation.

Progressively structured, with the density of the fiber layers increasing towards the clean air side. This ensures an optimum in terms of defined filter performance and dust holding capacity, coupled with a low pressure drop.

Robust in sustained use, high operational dependability and reliability even in the face of extreme moisture and wet conditions. They enable the energy-efficient operation of air conditioning systems. This translates to energy cost savings and a reduction in CO2 emissions.

The premium class in patented quality. Highly stable filter designs for the greatest possible operational dependability even under extreme loads. Water-repellent. Long service life, making them very economical.

The best choice for air filtration at temperatures above 100°C up to a maximum of 385 °C. The silicone-free filter elements meet particularly stringent requirements for air purity, process dependability and cost-efficiency.

Versatility for longer service lives: for use in prefiltration of ventilation and air-conditioning systems to protect downstream fine filters and as edrizzi post-filters for separation of overspray.

Language / Country

Language / Country